Haven't been on much lately, mainly due to work and a few old and new projects that I'm trying to manage on a budget(not because I can't afford it, but because it's a challenge...you get me

So today I would like break the routine and finally sit down and ask for your help (some of you still believe the myth that I'm a crossbow guru

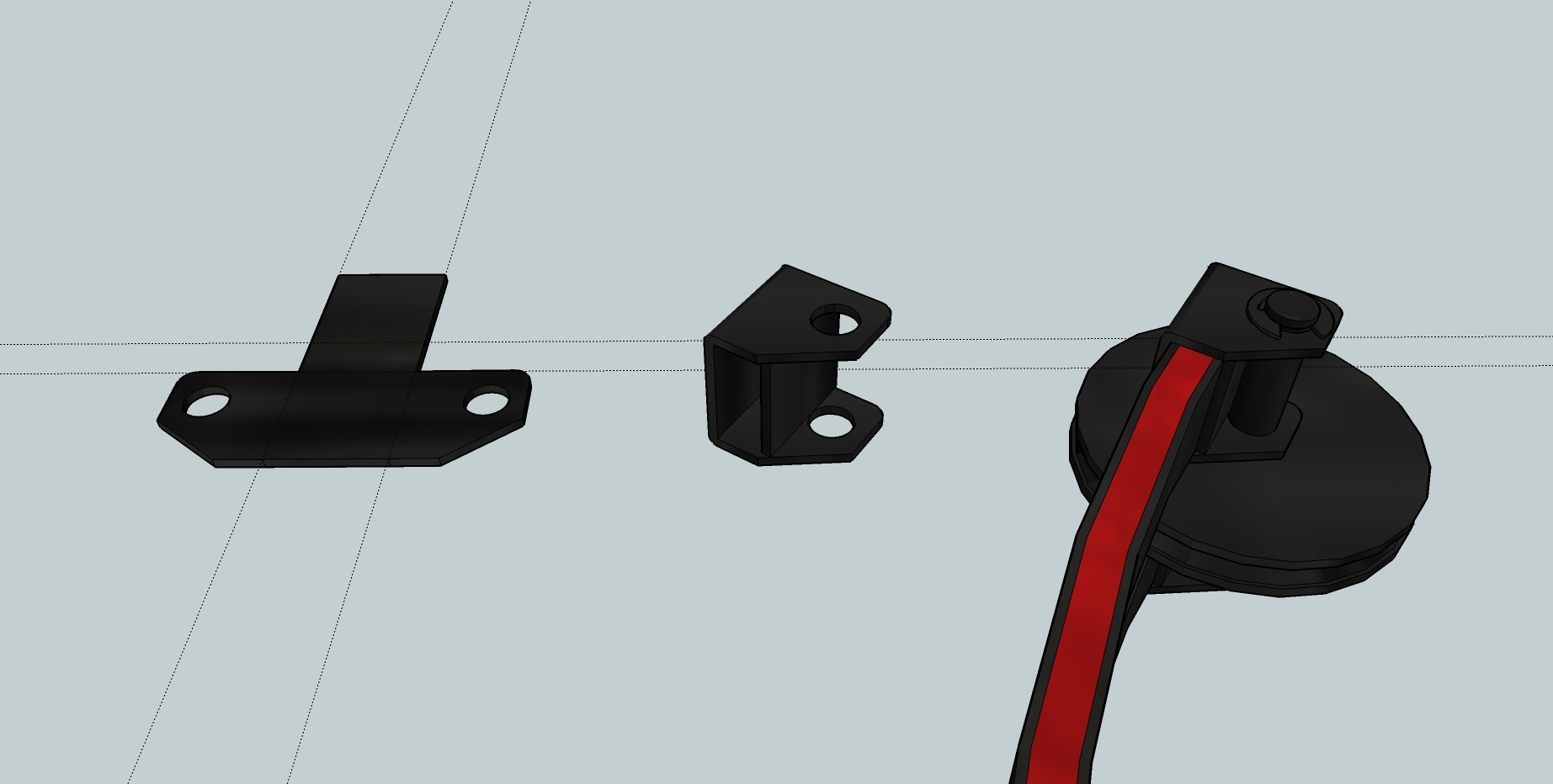

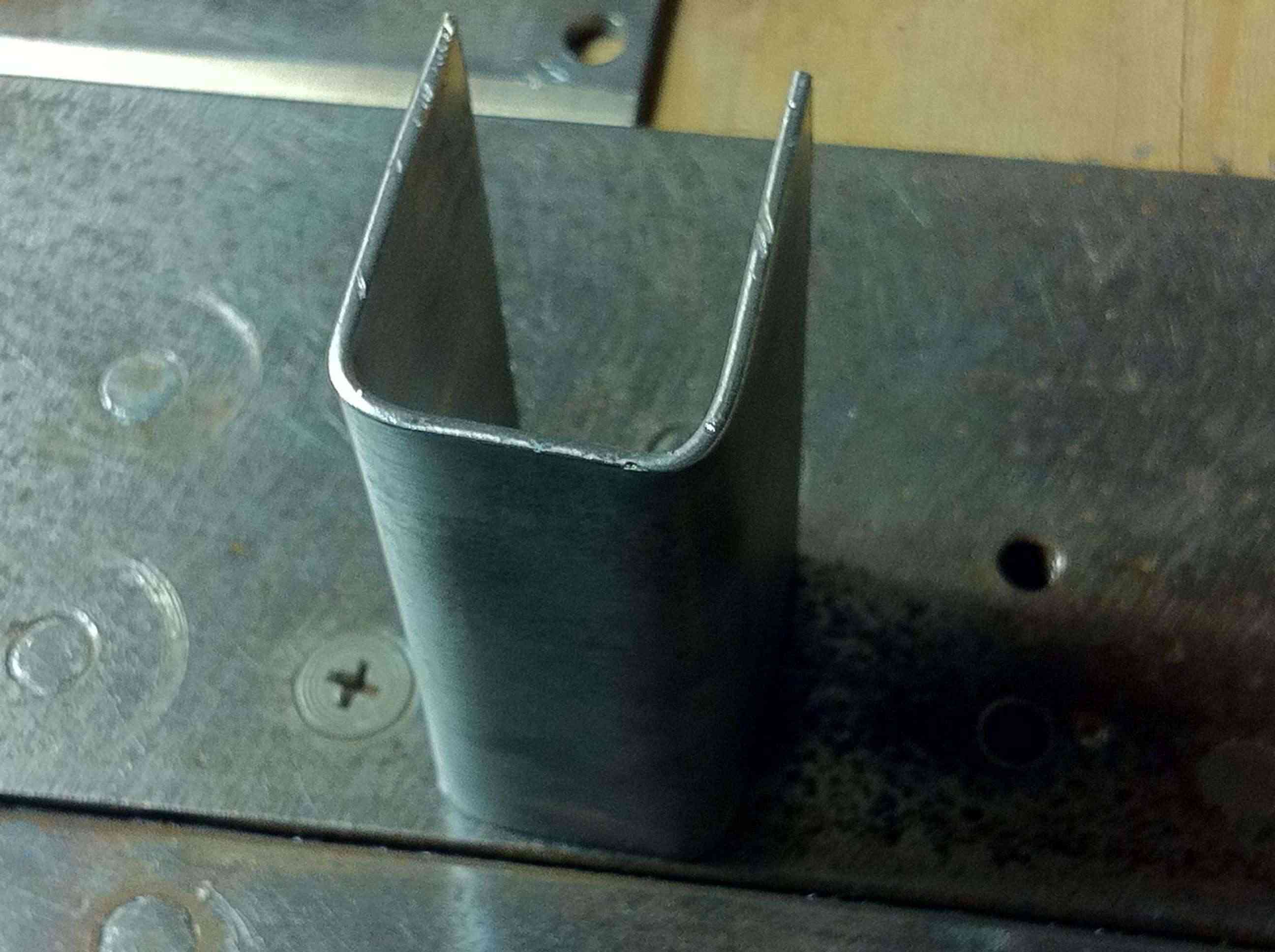

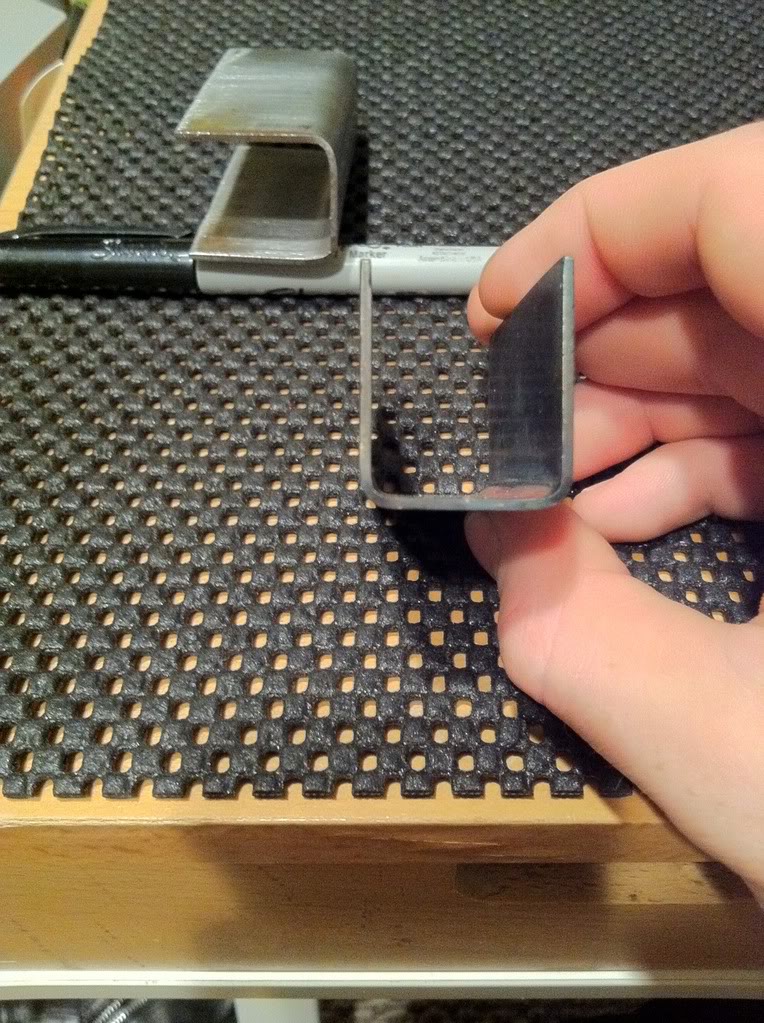

So I was working on this one bracket design and in CAD everything folds perfectly, however approaching the actual sheet metal business turned out to be a bit problematic.

The material is 16ga steel (is that still considered sheet or plate?

.

.The quirky part is the bend on the inside of the bracket...if you guys have any advice on the issue and specifics of bend allowance(compensation?) for 16ga range metal...I would greatly appreciate your input.

Thanks,

Ivo

PS: I hope this topic doesn't stop on this one question's resolution and we can discuss sheet metal further as I believe it has great potential in crossbow building that not many people realize.

)

)

Had a few tools break on me in the shop, but just before that happened I was able to get some work done on the brake.

Had a few tools break on me in the shop, but just before that happened I was able to get some work done on the brake.

Private messages

Private messages