Been looking at some metal bandsaws on the net...was on the verge of buying it, but in the last minute some unexpected expenses popped up (things break and need repair  ) and once again I'm back to ~ "can't afford it".

) and once again I'm back to ~ "can't afford it".

Either way, I thought it was a nice find and I thought I'd share it with you guys and hear your thoughts.

http://www.amazon.com/gp/product/B001D6PJAQ/ref=olp_product_details?ie=UTF8&me=&seller=

http://thehobbyistmachineshop.com/shop26.html

$300 for a bandsaw this cute...hmmmmm ...I kinda like it.

...I kinda like it.

Since the work we do does not require brutality of heavy machinery 90% of the time, so this might just fit the bill. I heard a lot of good things about Proxxon guys, if you guys also have something to say, I'd be delighted to hear your thoughts (perhaps even your own quick reviews of this or similar saw)...

As much as I love my Nicholson hacksaw,

...sometimes I just want to buzz through something using a nice straight fence,

...know what I mean?

Ivo

Either way, I thought it was a nice find and I thought I'd share it with you guys and hear your thoughts.

http://www.amazon.com/gp/product/B001D6PJAQ/ref=olp_product_details?ie=UTF8&me=&seller=

Proxxon Micro-Bandsaw MBS/E

After a recent experience with a Chinese made

product, it is indeed a great pleasure to examine and report upon a

Proxxon machine. This machine is the Proxxon MICRO bandsaw, MBS/E. I emphasize the word micro so there is no delusion on what this product represents.

I have a small metal cutting bandsaw from Lathemaster and also the extremely popular Delta 14" woodworkers bandsaw. The MBS/E

saw fits a different purpose altogether so therefore stands in a class

of its own. If you are a hobbyist model builder, this is an absolute must for your workshop.

I like bandsaws probably better that any other

kind of saw. Of course there are limitations, as they can not do inside

cuts. But I like the fact that the blade is always traveling in the

cutting direction, no lost motion. I also like that the blade's cutting

force is down against the table and not kicking back like a rotary saw. I

feel safe getting my fingers close to the blade but of course realize the danger.

This saw with it's variable speed (395 to 820

Ft/Min) is perfect for cutting sheet stock, tubes, small bars from out

of almost any material a model builder chooses with which to work. I

have already cut some sheet brass and steel with little to no effort. The saw does the work.

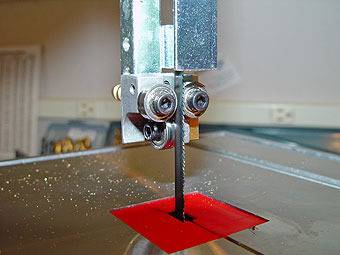

This is the saw out of the box without the table

installed. I immediately noticed some slight changes from the pictures

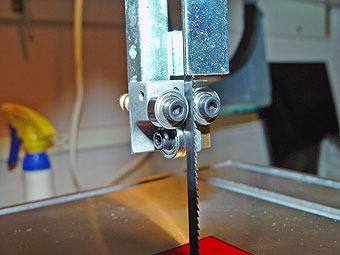

supplied by the manufacturer. The main switch is now a heavy duty toggle rather than a push button magnetic switch. The blade guides are now the ball bearing version

which used to be extra cost. I ordered a pair, now extra, as I was

going to install the better guides anyway. Nice that it is now standard.This is the rest of the parts in the box except for the 24 TPI blade on the right

that I ordered extra. The standard installed blade is 14 TPI. The is

also a narrower depth special temper 14 TPI blade available as well as a

diamond blade. The diamond blade requires the water cooling kit and

will add an additional $185 or so to the cost of the saw.

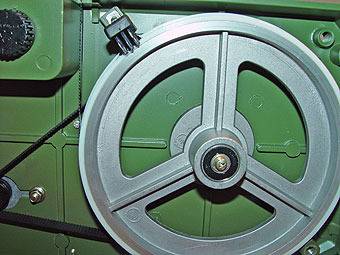

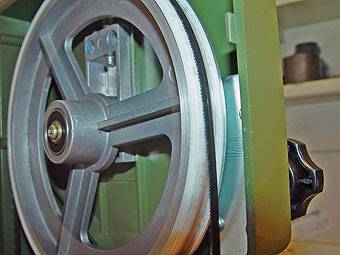

This is a speed selection recommendation chart. It is mostly all yellow so I don't see it as much value. The speed control is not linear, at least from the motor sounds. The speed control is more logarithmic than linear. That could be intentional design due to the built in speed compensation mentioned in the manual. An overall look inside the case. The wheel diameters are slightly over 6 inch.

The dark green case is die-cast aluminum. Plenty rigid for this

purpose. The yellow front is plastic and is chained to the rear case

near the center.Here is an unexpected feature. The bottom wheel has a brush that scrubs the tire of debris. Note the wonderful looking die cast and machined wheel. There are two ball bearings per wheel. One on each side. Here you can see the big (red) main switch with

removable lock pin (yellow). The black knob to the right is the speed

control. There appears to be plenty of adjustment to the motor for belt tension.

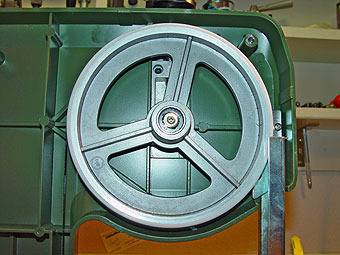

The upper wheel is as impressive looking as the

bottom one. Two ball bearings here also. The tires on both wheels is

some sort of plastic/rubber and can be replaced if/when needed.The axle plate on the bottom is bolted on with

three screws. Again, a very good looking part. You will have another

look further down in this series.Both the top and bottom tires have a

flange on the rear edge that prevents the saw blade from slipping off

the back of the tire. That is a good idea as that is the direction the

blade is pushed when making a cut. The blade could be pushed off the

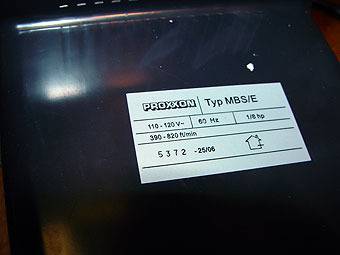

wheel if the blade guide bearing is not properly adjusted.The top knob is blade tension adjustment. The middle knob locks the blade tension and has some effect on tracking. (More on tracking later.) The bottom left knob is the adjustment lock for the blade guide The back of the saw. The motor and speed

controller is completely covered. The ventilation slots are fake. The

black tube on the bottom left is the vacuum connection. The three black bolts are the bottom wheel shaft mounting.The machine label indicates the motor is 110-120 volt 60 Hz and 1/8 HP. This is entirely adequate

for the size and purpose of this small light duty saw. I have

deliberately stalled (tested) the blade and motor with overly aggressive

feeds in brass with no harm. Just let the blade and motor do their

work. There is not a lot of rotational mass (momentum) in a tool of this

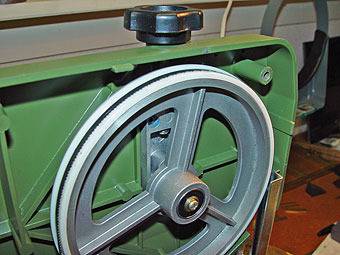

size to overcome heavy feeds.With the cover open it can be seen that the bandsaw is not very wide. The base is in fact too narrow

front to back. The product manual recommends the saw be screwed to a

bench or a wider base. I am going to make a wood base extending as wide

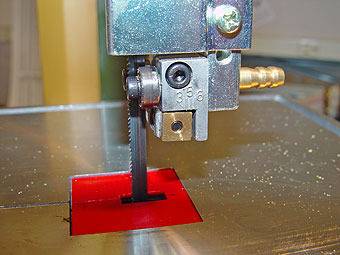

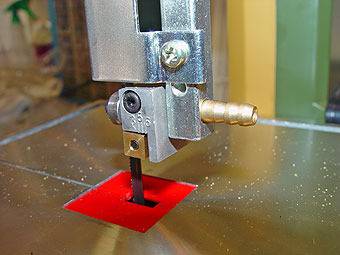

as the motor both rear and front.This is another unexpected cool feature. The four front cover bolts are captive. No loosing these bolts when the cover is removed. This is the die cast table. Talk about polish!

The coolant trough is cast in but looks machined. The T-slot (yes,

T-slot) IS machined in. The center is a replaceable plastic part.Another step of quality. The saw blade entrance slot is bolted to maintain alignment. The bottom of the table looks as nice (without

polish) as the top. Look at the hefty mounting/angle plate. The taped

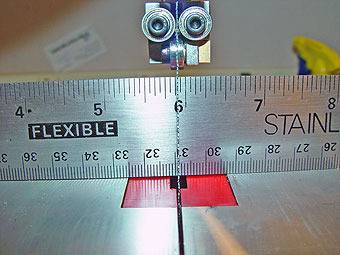

holes in opposite corners are for the water exit from the coolant trough on the other side. Extra parts are provided in the optional water cooling kit.Simple design but the table locks very secure. Just another look under the table. The saw blade enters the cover here. I don't know how warm the motor may become. This kind of band sawing is not usually heavy duty or long term. Here is the new blade package. Several 42 inch blades are available including a diamond blade that requires the water cooling kit. This is the triple ball bearing blade guide. It was installed on my test machine so it must now be standard. A miter gage is provided with the saw. Another quality detail is the T-Slot in the table. Quality IS in the details. I set the table angle with the precision square.

The center insert is a bit too low and the table edge will snag small

parts. This insert could be be shimmed or a new insert (brass?) made. If

you don't intend to angle the table the slot could be much more narrow.Another overall look at the saw. This time with the table mounted. Close up of the vacuum port. The tube to the left is soft rubber and is (I assume) some sort of adapter for the vacuum hose. Here is the top blade tension adjuster. I noticed the two hex screws at the top function as tracking adjustment by tipping the plate at the top. Here is another look at the bottom wheel. Note the rim on which the belt drives, has no teeth. The toothed belt runs like a flat belt. This may provide some motor / controller protection from a jammed saw blade.

In the bottom right corner is a little slide that can be removed to let the chips fall out if the vacuum port is not usedI examined the adjustment plate and added some more thread locker to the tracking screws. I could see there was already some on the threads. I adjusted the tracking until I got the blade to

track where you see here, just off the rear flange of the tire. It

required about one turn on both screws. This provided improvement from out-of-the-box running.It can be seen that I have been cutting some brass before this picture. This is the 24 TPI blade. This brass barb is where the water connects if the user desires water cooling on the blade. The blades are claimed to have very long life

and it can be seen in their design that the teeth set and built in wave

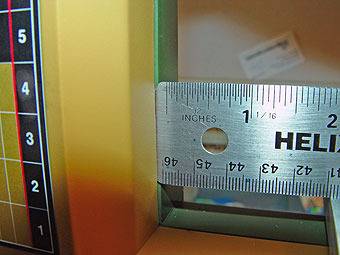

set are designed to provide very good kerf and cut tracking.I am measuring the throat. Book says 5 29/32 (150MM)... ... but I have some extra space at this end. Overall available head The total machine is height is a little over three inches. The overall machine is about 19 inches with the knob The overall width at just the base is 12 inches. The saw runs quietly like my Delta wood bandsaw.

You know it is running but the noise is not loud or objectionable. The

gentle sound can make you lower your guard.

Cutting metal of course still makes some noise. Ear protection

is recommended as well as eye protection. As small as this machine is...

it is still a power tool and there are certain inherent risks. It is

not a toy saw to be given to a young child without supervision.

The quality I saw (and show here) will make this a favorite

tool for anyone who uses it. It will also last a long time as it is not a

minimal built product.The space in front of the blade is almost 4 inches. This saw is not designed to be a

competitor with full size band saws. Don't buy this one if you have full

size work to be done. If the need is to cut small parts from thin

materials then this saw will do it quickly and with style.

My intention at THMS is to use it for cutting small steel,

brass and aluminum parts for use in my machining projects and metal

constructed models. This is a must have tool for anyone building scale

models from real life materials. Small scale live steamers, scale boat

builders, doll house details come to mind. This saw is a "big brother"

companion for the type of work done with a scroll saw as it has a larger

blade. It works best for less detailed and straighter cuts.

Update: I have installed the Proxxon bimetal

blade and have found this saw to be an excellent tool for cutting metal

for use on my A3 Locomotive project as well as any other metal parts I

have tried. The blade is the most expensive of the blade selection, but

makes the MBS/E saw a true metal cutting miniature bandsaw for the

machine shop.

It will cut thin (1/8" -1/4") wood with little problem. Thick

(3/4") very soft wood such as basswood or balsa tends (in my experiance)

to load up the fine teeth on the 14 TPI blade and such use is not

recomended by me for this saw. A 6 or 7 TPI skip tooth or raker blade

would be a better choice for sawing soft wood, but is not supplied by

Proxxon.

The blade length is 42" and is smaller than (say) the Delta

blades. I haven't yet found a second source for 42" blades. However, the

Proxxon blades seem high quality and should provide long life in hobby

type service.

Bottom line the Proxxon MBS/E is a very good micro bandsaw. It gets high marks from THMS. Stop drooling all over your keyboard and go order one.

http://thehobbyistmachineshop.com/shop26.html

$300 for a bandsaw this cute...hmmmmm

Since the work we do does not require brutality of heavy machinery 90% of the time, so this might just fit the bill. I heard a lot of good things about Proxxon guys, if you guys also have something to say, I'd be delighted to hear your thoughts (perhaps even your own quick reviews of this or similar saw)...

As much as I love my Nicholson hacksaw,

...sometimes I just want to buzz through something using a nice straight fence,

...know what I mean?

Ivo

Private messages

Private messages