"P-G makes his roller a bit shallow, at 3/5 below the top edge of the socket and 2/5 above. I recommend you bury the roller 2/3, with 1/3 protruding. That will give you a much stronger socket. If you bury it as much as 3/4 of it's diameter, you won't be able to take the roller out of the top of the socket.

P-G places the sear-plug, where the trigger/tickler bears against the nut, almost precisely at the bottom of the nut. If you move the sear around toward the rear of the nut by, say 5 mm. You will get a stronger lock, since the trigger takes more load and the upper edges of the socket are stressed much less."

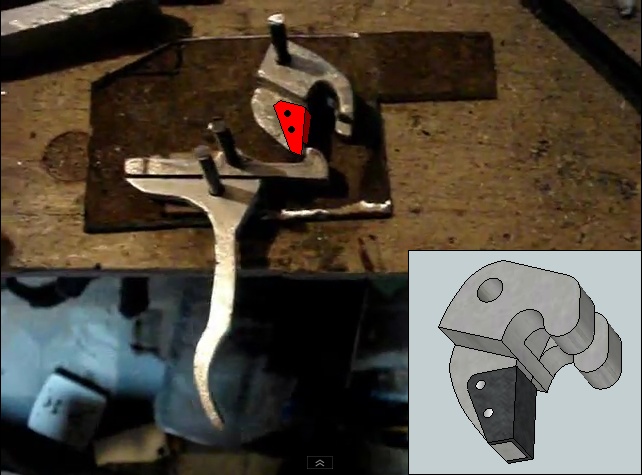

Robin Allen made the elkhorn nut and a steel socket for my med, and it is impossible to pull the nut out from above because the recess is purposely made deep enough to prevent the nut from being pulled up and out by the string load before release. This undoubtedly is an important safety feature where draw weight can easily excede the strength of the axle pin or lashing.

And how did Sir Ralph Payne-Gallwey securely fasten the metal sear-plug into the horn nut? There is a lot of friction applied at this point when the tickler is pressed and the engagement points begin to slide apart. As for his depicted trigger mortise I have to wonder: Did he ever make one like that? If he did he must have used special trained woodworms

Pavise

Private messages

Private messages