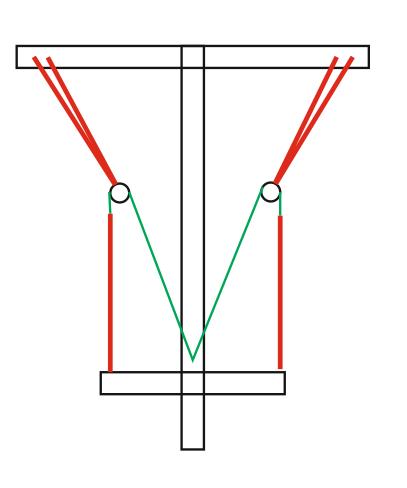

To get faster you need to employ some kind of mechanical advantage like levers or pulleys. But some of the MA is eaten away by inertia mass and friction from the added parts this will take.

I want to test different pulley systems for speed and see if there is a gain to be had. If I find something reasonable that works I want to build a rubber powered crossbow comparable in draw weigh and no larger in size than commercially avaliable high end crossbows and hopefully get it as near as possible to contemporary arrow speeds. Lets see what rubber can do!

I omitted the roller setup because with thicker rollers at front the string would have been riding too high over the rail. This would have needed a redesign of my test rig so I will do this last. I just build a simple stationary test rig from some scrap wood I had in the shop. Nothing fancy or elaborate just enough to test some pulley systems on it.

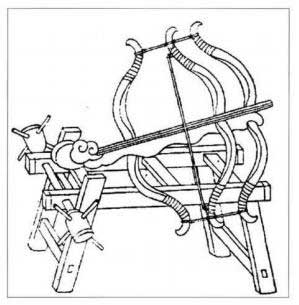

I started the test with the 2:1 pulley system, here is the setup:

Spanned:

The Arrows:

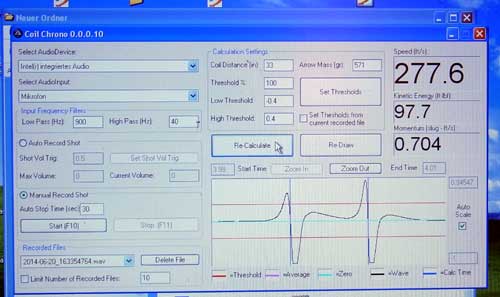

Draw length is 70cm and draw weight on the trigger is app. 80lbs I use coil chrono to record the speed.

Results:

The 37g(571gr) arrow (equals a 21mm steel ball) was shot 5 times and the speed recorded:

1. 221,66fps

2. 222,31fps

3. 222,46fps

4. 223,16fps

5. 223,24fps

Average: 222.56fps

The 22g(339,5gr) Arrow (equals a 17,4mm steel ball)

1. 272,73fps

2. 273,01fps

3. 272,84fps

4. 270,77fps

5. 272.56fps

Average: 272,58fps

The 12g(185,2gr) Arrow (equals a 14,3mm Steel ball)

1. 346,46fps

2. 348,28fps

3. 346,45fps

4. 345,83fps

5. 347,25fps

Average: 346,58fps

I am using Theratube silver. According to other peoples findings its max speed if used directly is about 55-60m/s =180-197fps

So this shows that ist possible to get some more speed from a simple pulley system.

The gain in heavier projectiles is as expected - not so very much but you can see that using lighter arrows the speed gain is noticeable.

This indicates that to shoot a large 37g arrow we will have to increase the draw weight considerably from what its now. But if the system was already maxed out or pulley systems would not work at all it would not have shot the light arrow at higher speed.

Try shooting a 14mm steel ball at 346fps using theratube silver directly- not possible I think even if you could do a butterfly draw with it.

You may also notice that I did not stretch the rubber to its maximum length - I only get about 170-180% elongation from the slightly prestreched loops here.

222fps for a 571gr arrow is a decent speed but not overly impressive so far. But keep in mind that high end crossbows usually range in between 180-200lbs in draw weight to shoot very fast arrows. We are nowhere near that here.

It would be nice to test this setup with 200lbs and see what it can do then, but unfortunately the ugly test rig is nor sturdy enough to handle such draw weights. I am hesitant to try because bad things may happen.

I will probably increase the draw weigh about as much as I dare but will do the other tests before.

The 346fps on the lighter arrow was nice but now we need to do this with the large one

So there is room for improvement. I can use higher draw weight, shorten the string or the rubber a bit(there is still some room) or I could use Theraband gold which is reportedly faster than slow silver tube.

But first I will do some more tests on the other pulley setups to see if we can get better than the 2:1 without having to resort to insanely high drawweights.

Using pulley systems with hand drawn slingshots is in my opinion not a viable way to use but employed in a really powerfull (150+ lbs) crossbow I think they can really increase the speed .

These are my first findings on the subject of rubber*pulleys and I am curious what the next one will do

Best Regards

Private messages

Private messages