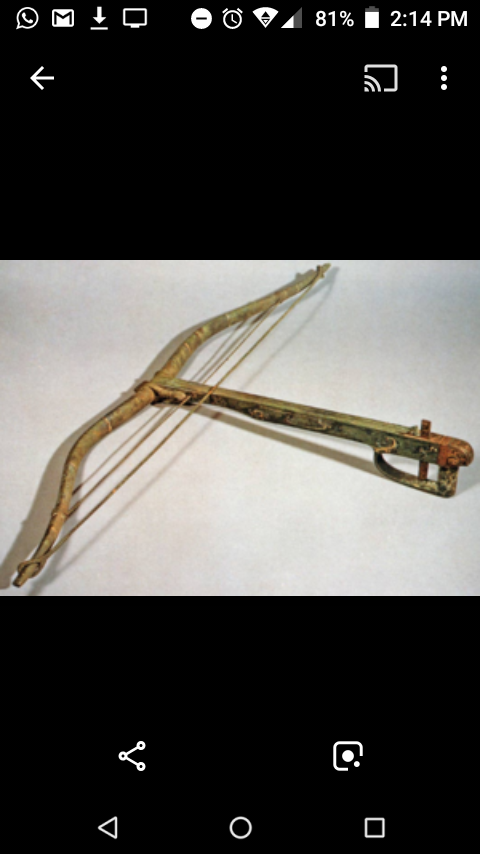

I am hoping to make a 300lb "Han dynasty style" Crossbow with a powerstroke of around 20 inches (so around 25 inch draw length). Considering the prices of Horn and sinew, I am most likely making the bow prod out of fibreglass or PVC, unless I can purchase a composite bow of that draw weight/length. Due to the material choice, the goal of this is to test the theoretical power of a Han crossbow by making similar dimensions in Powerstroke and draw weight.

So far on the internet, I have not found a single example of such a crossbow replica, so hence this project. (Most examples of these replicas look like they have a maximum draw weight of under 70lbs )

Due to my lack of experience in fibreglass bowmaking, hoping to get some expertise knowledge from anyone. Would be great to know where I can get fibreglass(and the specific type) realistically for this type of monstrous prod. Just hoping to know when I walk into a FRP fibreglass supplier shop for construction, I can tell them the exact fibreglass type to order. Most likely for my first attempt the prod will not be re-curved and will have a simple D shape for simplicity. I would be glad to add siyahs but without any experience please contact me for suggestions on how to attach the siyahs for such a heavy draw weight as I am worried about the glue. Considering the modulus of elasticity of fibreglass, the bow prod would need to be around 5 feet long with a average width of 3 inches I'd assume.

My Main concern is making the crossbow trigger right(will be using steel for trigger parts due to acessibility) and I will be using dacron for the string material. So clearly you can see the focus is less on historical accuracy, but rather to test the theoretical power of such a weapon.

If I had the historically accurate materials and skills to make a horn and sinew replica, I would be glad to. But so far I have to start somewhere. I have made crossbows out of spring steel before but nothing asiatic.

The article that inspired me to make this: cannot post link due to new member

Also if you are wondering how is this different from a modern fibreglass bow? Most of them have a draw weight limit of 200lbs but their bow prod is only 3 feet long. Considering the elasticity of fibreglass, it cannot have a long powerstroke while being that short. By increasing the bow prod to 5 ft or 6 ft, we can increase the maximum elastic deflection, hence more powerstroke, while sacrificing portability.

btw also making a repeating crossbow version with a 110 lb horsebow with a 26 inch draw length. It will probably end up being more of an artillery piece but it will be a lot of fun.

So far on the internet, I have not found a single example of such a crossbow replica, so hence this project. (Most examples of these replicas look like they have a maximum draw weight of under 70lbs )

Due to my lack of experience in fibreglass bowmaking, hoping to get some expertise knowledge from anyone. Would be great to know where I can get fibreglass(and the specific type) realistically for this type of monstrous prod. Just hoping to know when I walk into a FRP fibreglass supplier shop for construction, I can tell them the exact fibreglass type to order. Most likely for my first attempt the prod will not be re-curved and will have a simple D shape for simplicity. I would be glad to add siyahs but without any experience please contact me for suggestions on how to attach the siyahs for such a heavy draw weight as I am worried about the glue. Considering the modulus of elasticity of fibreglass, the bow prod would need to be around 5 feet long with a average width of 3 inches I'd assume.

My Main concern is making the crossbow trigger right(will be using steel for trigger parts due to acessibility) and I will be using dacron for the string material. So clearly you can see the focus is less on historical accuracy, but rather to test the theoretical power of such a weapon.

If I had the historically accurate materials and skills to make a horn and sinew replica, I would be glad to. But so far I have to start somewhere. I have made crossbows out of spring steel before but nothing asiatic.

The article that inspired me to make this: cannot post link due to new member

Also if you are wondering how is this different from a modern fibreglass bow? Most of them have a draw weight limit of 200lbs but their bow prod is only 3 feet long. Considering the elasticity of fibreglass, it cannot have a long powerstroke while being that short. By increasing the bow prod to 5 ft or 6 ft, we can increase the maximum elastic deflection, hence more powerstroke, while sacrificing portability.

btw also making a repeating crossbow version with a 110 lb horsebow with a 26 inch draw length. It will probably end up being more of an artillery piece but it will be a lot of fun.

Private messages

Private messages