Hi,

The sequence will have to start with the prod. Once you have a properly tillered prod, you will know the draw length and poundage. From there you will decide how long to make the arrow track. The trigger can be made first or last, doesn't really matter, but having it before building/routing the track might prove more useful if building the track as a separate component. The stock comes last, especially if stock and track are separate components, but really the final fitting/adjustments are made when all other components are complete.

So basically:

Prod>Trigger x Stock ... for a crossbow employing a solid stock that has a track groove routed in it.

Prod>Track xTrigger>Stock ... for a crossbow with a laminated track(separate from the stock)

To start with the prod, you can check out our Wiki(New Member & Useful Links on the side of the forum) where our friend

basileus explains how to tiller a leafspring, how to make bow irons, as well as a few other helpful notes on building. Also there is an article from Popular Mechanics that has some plans. >>>Link

There is a download link called something like "Metal bowed Crossbow

Plans". Nice little article and has some info on what poundage to expect

from what prod dimensions, but other than that I would not go for their

trigger as there are much better designs.

I think it's also worth mentioning that leaf spring prods are notorious for occasionally snapping and possibly wacking one in the head...though it is rare that we hear "true" stories(mostly paranoid people yapping), but the few real ones come from bystanders, as dead men tell no tales. As scary as that may sound, an it is, I'm only saying this to get to my next point...

precaution...a safety backing or cover is used to help avoid coming "head to head" with a prod shard. One may use several stainless steel wires layed out on the back of the bow and secured by wrapping with string(as was suggested by one of our members)...or leather sleeves can be sewn tight over he limb (like a corset

). There are a few examples here on the forum showing this practice...New World Arbalest crossbowyers do it and it looks pretty classy.

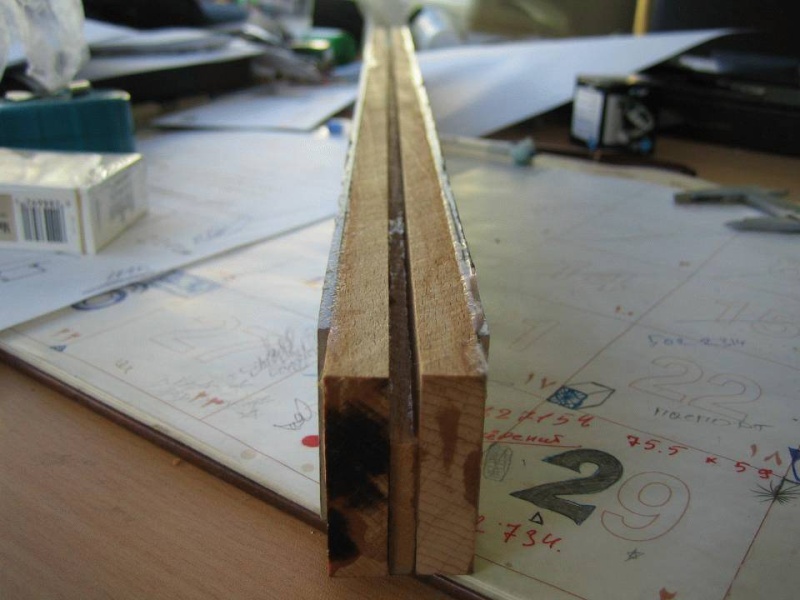

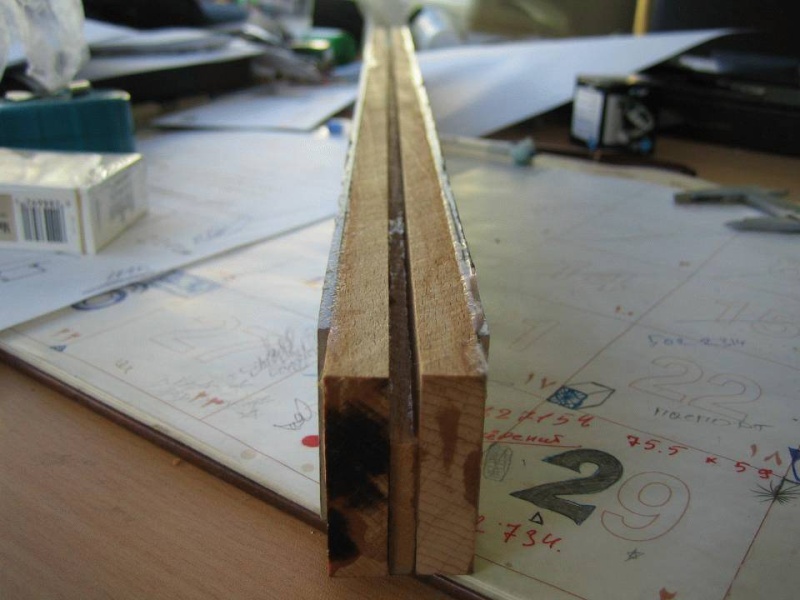

The track can be, as Todd said, made with a router right in the stock by either using a V bit or for a deeper one(for groove allowing the use of three fletch arrows) a few passes with a thin U bit. If you have no access to a router and or want to make a track as a separate component, the track can be laminated out of wood/plywood and faced with strips of aluminum.

I also epoxied aluminum angle on top...but a wooden track is fine.

There is an article on our Dear Departed Robin Allan's website, that touches ends on track groove dimensions and how they relate to arrow shaft diameter. >>>Link

A really nice site with some excellent articles that might answer quite a few of your questions, just check out the Hints&Tips section as well as it's extension Archives at the end of the Hints&Tips page.

The stock is again another discussion, what kind feeds your soul?

There are a few designs that I can think of...

There is an open grip shotgun style...which is good for quick shouldering of the weapon, but a little more sensitive to the angle of the grip and grain of the wood....the more the handle represents a pistol grip, the more grain begins to play a crucial role.

Thumb hole/Pistol grip stocks...which are pretty cool. Thumb hole stock might be a little slower in shouldering(never really felt the difference though), these I heard are better for target shooting. Thumb hole stocks also have an added bonus, since a thumb hole/pistol grip stock can be made with a set forward grip - a more compact and better balanced crossbow can be made.

...or an over the shoulder stock pistol crossbow...

...or if you'd like... a bullpup crossbow(haven't seen too many of those running around)

We did a Custom Stocks topic on here, where I was able to translate an article which talks about how to take shooter's measurements. Here is a

>>>Link But then again there is "sort of" a way around it, I mean I try to cheat the system occasionally when explaining things to my brother, and we devised a way to get our shooter dimensions by feel, using a few carpenter squares(and the like) clamped together.

...which resulted in a pretty bad ass and surprisingly comfortable stock.

Template

Roughly shaped stock

Rough shaping was done with this little duo...

Finished and Primed

Finished and Primed

The cheek piece is a little out of place causing one to slightly stretch his neck to position the head properly for scope use, but other than that the kid is pretty happy and shoots the thing even though it's not finished.

The triggers topic was moved to Basket since it was a damn mess and I

was thinking of splitting it into three or even four topics covering Medieval

Tickler triggers, Medieval Set triggers, Classical Triggers, Modern

triggers - covering each separately. I'll bring it back and it will be in the Classical

Crossbows forum until I write up better organized trigger topics.

However there are two basic

under claw sear triggers I can think of off the top of my head the basic one for a openhandle/regular thumbhole stocks and one with an extended trigger for set forward grips, I'll sit down to draw them up as close as possible to functional blue prints and will post them in the new triggers topics, till then you are welcome to visit our first attempt at triggers topic.

Well, hope I helped out a bit...I mean it's just general view on things and there is plenty for you to read up on and have a blast researching. Check the Crossbow Books topic(just use Search) and it will bring up some good info, one I find most helpful in regards to triggers was Man Powered Bullets.

Good Day,

Ivo

Private messages

Private messages