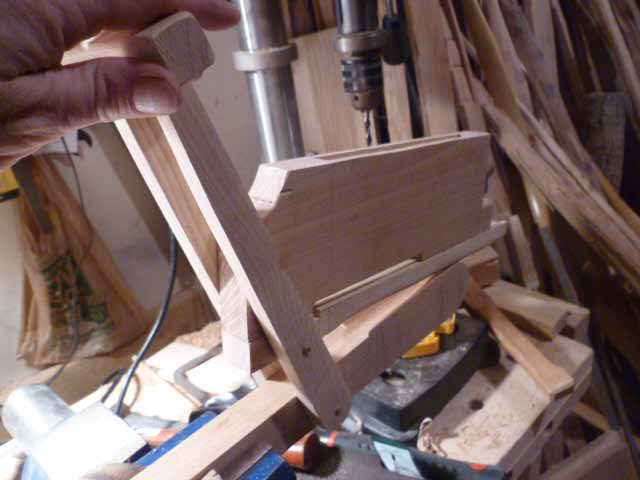

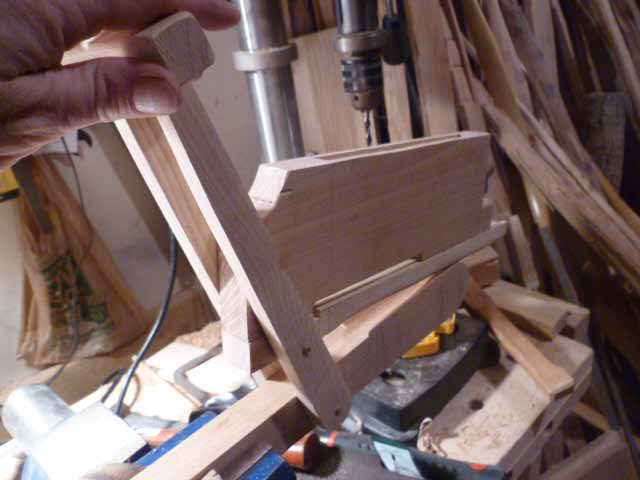

So far, this has been a real pleasure to build. Tuesday some bamboo is coming from a vendor so I can get the bow built and installed, as well as some cedar shafting to make the little bolts. What is neat about this project is that I have been able to use scrap hardwood, so it isn't costing me much. Aside from the bolt materials (already had some field tips sitting around I can use) and two 1/'4" brass threaded machine screws and washers, plus the bamboo slates, there has been no special outlay of money.

I expect to have this little weapon completed in the coming week or two, and will eventually post more photos and video of the weapon in action. If anyone wants, I can do a quick buildalong. These are just random photos to show various stages of progress.

Dane

]

[IMG]https://2img.net/h/i630.photobucket.com/albums/uu30/Danemitchell/P1010343.jpg

]

]

]

[url=https://thearbalistguild.forumotion.com/

]

] [/url]

[/url]

Private messages

Private messages