I had several goals with this build, which is basically version 2.0 of my first pistol, https://thearbalistguild.forumotion.com/t618-crossbow-3-pistol-1

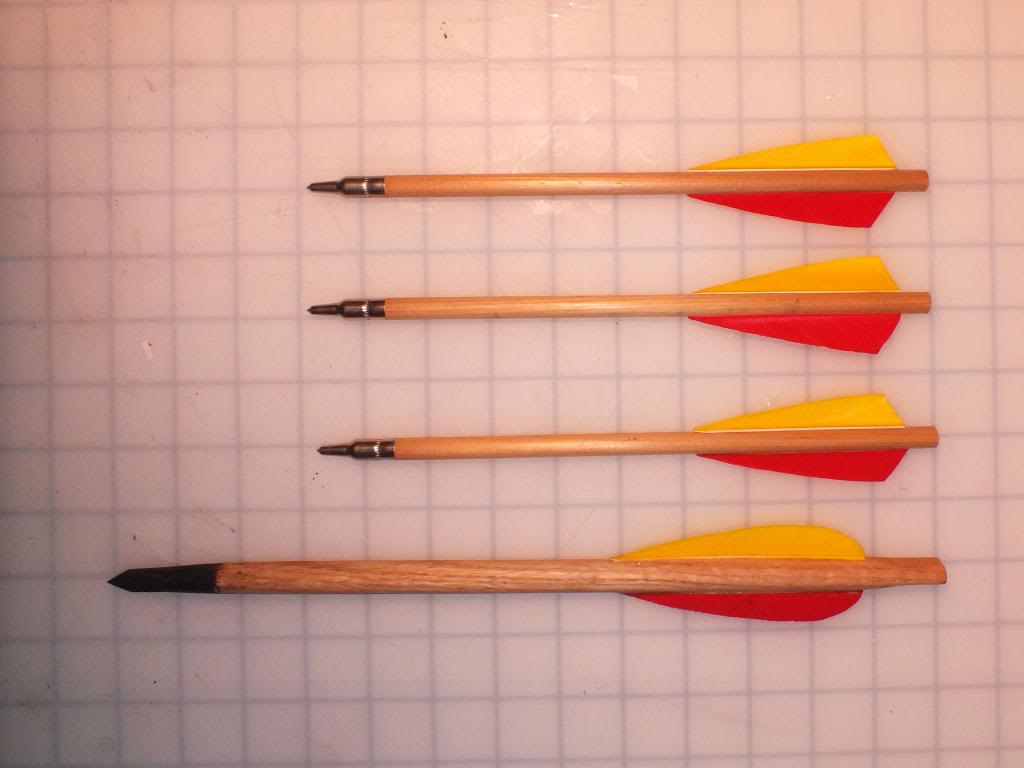

Of course I wanted to increase the power, which was accomplished by adding another inch of draw and another leaf to the spring- there are two full length steel prods (here's an Amazon link if you'd like to know what I'm referring to: http://www.amazon.com/Performance-Crossbow-Metal-Replacement-Prod/dp/B009XXGA18/ref=sr_1_3?ie=UTF8&qid=1362316775&sr=8-3&keywords=steel+crossbow+prod), plus one cut to about 2/3. I've got another piece on the bench cut to 1/3, to be added later if I think it can take it.

I also wanted to use up stuff I had lying around the shop rather than spending any money, it is tax season! So far so good there. The stock is a laminate with a 1/4" bloodwood center, then 14" red oak running the full length, more bloodwood up front and 1/8" bubinga to beef up the nut socket and grip area.

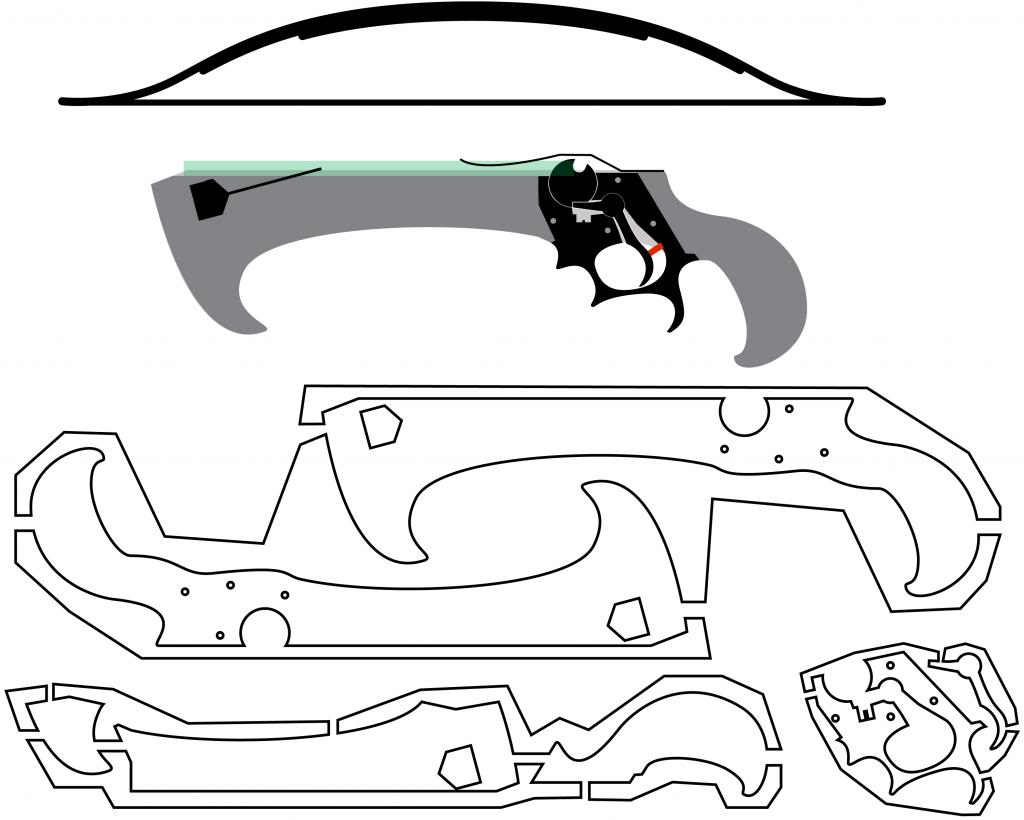

Most interesting, to me at least, is the lock/release mech, made from 1/4" Delrin sheet. I'd been toying with this idea for a while, and for this initial use I kept the mech design simple. There are no steel axle pins, the pins are just to make sure the trigger housing stays rigidly in place. Four was overkill, I determined, two pins would have been plenty. The whole assembly slides in from the bottom and the fit is very precise. Before you start oohhing and ahhing over the crazy carving skills required for achieving this kind of precision, I better confess that I designed it on the computer and cut the mech, center bloodwood, and red oak using a Zund digital cutting table with a router module http://www.zund.com/index.asp?topic_id=2485&m=2485&g=2529

I stole the nut from my first pistol, I'll have to make a new one to get that unit back together. I didn't think I needed a sear insert on that one since it was low pressure, brass on delrin, and I think I need it even less here where it is delrin on delrin. I've test fired this beastie a few dozen times and so far the mech works beautifully- the pull is smooth, precise, and essentially effortless, and so far no appreciable wear or deformation.

This is my first attempt at a cord-bound prod. Well, truthfully, what you see here is my sixth or seventh attempt at tying on the same prod! I tried a lot of different materials I had lying around before settling on the paracord, mainly because it was all I had left. After having to cut off so many attempts and start over so many times, I decided to work toward a method that could be untied fairly easily, and that's what we see here. That's one piece of cord about 7 feet long, centered in the hole and wrapped around the prod twice on each side, looped around the bundle about 13 times and then drawn back through to exit the bundle at the rear. I then drew it tight and pulled it under the bundle against the stock to further tighten and secure it, and wrapped the excess around each side of the prod and tucked it under at the ends. I did not cut off the extra length because it is required for this method, the wraps have to stay loose enough to pull the cord back through before tightening down. I wrapped the bundle around my finger and the loops going around the prod to keep things straight and then pulled the wraps tight one at a time.

I had to put leather pads over the ends of the 2/3 length prod leaf, no matter how I smoothed and shaped the ends the string would get cut there every time I fired. I used up three strings before I solved that issue. I don't want to wrap the entire prod, but I don't want it to look like crap like it does now, either. Right now there is a section of bicycle inner tube around the prod inside the socket to cushion and tighten that fit, it's ends tapered with holes in them that are looped around the pads. So right now my leaf-spring prod assembly is functional but ugly, and that won't do.

Oh, and another issue with my first pistol is that it was difficult to cock since there was nothing to hold onto for any kind of leverage. D'oh! That's what the "horn" on front is for. I've got a cocking rope I modified for this one that has only one handle, with both ends of the rope attached. My idea was that you would hold the "horn" in one hand and draw back the cocking device with the other, like drawing a standard bow or slingshot. I've done it, but it doesn't work well for two reasons- first, I'm not as strong as I think I am, and second, the angle is wrong, as in there shouldn't be any angle. Your grip on the stock would have to be in line with the tension of the string, like a stirrup is usually placed, or else the stock wants to tilt and wiggle away and the string and nut don't want to meet up. So instead I put that horn under the arch of my foot, steady the stock with one hand and draw with the other.

I'll also need to make my own strings. I've been using the strings that came with the prods, but they aren't up to this much tension. They tend to stretch rather than break.

Last edited by Gnome on Sun Mar 03, 2013 8:56 am; edited 1 time in total (Reason for editing : spelling)

Private messages

Private messages