Last edited by ferdinand on Fri Jan 25, 2013 8:24 am; edited 8 times in total

Latest topics

» 12th Century Chinese Crossbow Chronographed

by stuckinthemud1 Fri Nov 24, 2023 3:50 pm

» Crossbow Stock

by kenh Tue Oct 31, 2023 6:19 am

» Colletiere a Charavines continuing experiment

by stuckinthemud1 Sat Oct 07, 2023 5:36 am

» Cocking - how

by stuckinthemud1 Thu Aug 03, 2023 4:24 am

» Questions around heavy crossbow lath buildin

by stuckinthemud1 Wed Apr 26, 2023 1:10 am

» Arab Crossbow

by stuckinthemud1 Tue Apr 25, 2023 7:57 am

» prod angle, and lever trigger for sale anyone?

by stuckinthemud1 Mon Mar 20, 2023 5:54 am

» flexible string

by jasper1978 Mon Mar 20, 2023 1:25 am

» [solved]Skane/Lillohus crossbow thread

by stuckinthemud1 Sun Mar 19, 2023 7:44 am

» jens sensfelder

by jasper1978 Wed Mar 08, 2023 11:58 pm

» 400lb Windlass crossbow bolts weight and accuracy shooting high.

by stuckinthemud1 Sun Mar 05, 2023 2:53 pm

» Codex Löffelholz crossbow

by stuckinthemud1 Tue Jan 24, 2023 4:14 pm

» Digitar prodsc

by stuckinthemud1 Sun Jan 15, 2023 2:42 pm

» Troubleshooting

by Andy. Fri Jan 06, 2023 12:29 pm

» Wood Prods

by stuckinthemud1 Fri Dec 30, 2022 12:47 pm

» Colletiere a Charavines crossbow

by stuckinthemud1 Fri Dec 30, 2022 8:54 am

» Simplified Löffelhotz speedloader

by stuckinthemud1 Fri Dec 09, 2022 4:05 pm

» Fiberglass H-bows

by c sitas Sat Nov 12, 2022 8:44 am

» Bad Antler

by drawknife Sat Nov 12, 2022 3:48 am

» Anyone make their own bolts?

by Juniper Mon Oct 17, 2022 8:20 am

» Josef alm in English

by Juniper Sat Oct 15, 2022 4:22 am

» Qin/Han lock drawings

by kenh Fri Sep 23, 2022 8:16 pm

» stirrup dimensions?

by stuckinthemud1 Thu Sep 01, 2022 1:49 pm

» Skane/Lillohus lockbow information needed

by stuckinthemud1 Sun Aug 14, 2022 6:23 am

» need help contacting le musee Dauphinois Grenoble

by stuckinthemud1 Sat Aug 13, 2022 3:22 pm

by stuckinthemud1 Fri Nov 24, 2023 3:50 pm

» Crossbow Stock

by kenh Tue Oct 31, 2023 6:19 am

» Colletiere a Charavines continuing experiment

by stuckinthemud1 Sat Oct 07, 2023 5:36 am

» Cocking - how

by stuckinthemud1 Thu Aug 03, 2023 4:24 am

» Questions around heavy crossbow lath buildin

by stuckinthemud1 Wed Apr 26, 2023 1:10 am

» Arab Crossbow

by stuckinthemud1 Tue Apr 25, 2023 7:57 am

» prod angle, and lever trigger for sale anyone?

by stuckinthemud1 Mon Mar 20, 2023 5:54 am

» flexible string

by jasper1978 Mon Mar 20, 2023 1:25 am

» [solved]Skane/Lillohus crossbow thread

by stuckinthemud1 Sun Mar 19, 2023 7:44 am

» jens sensfelder

by jasper1978 Wed Mar 08, 2023 11:58 pm

» 400lb Windlass crossbow bolts weight and accuracy shooting high.

by stuckinthemud1 Sun Mar 05, 2023 2:53 pm

» Codex Löffelholz crossbow

by stuckinthemud1 Tue Jan 24, 2023 4:14 pm

» Digitar prodsc

by stuckinthemud1 Sun Jan 15, 2023 2:42 pm

» Troubleshooting

by Andy. Fri Jan 06, 2023 12:29 pm

» Wood Prods

by stuckinthemud1 Fri Dec 30, 2022 12:47 pm

» Colletiere a Charavines crossbow

by stuckinthemud1 Fri Dec 30, 2022 8:54 am

» Simplified Löffelhotz speedloader

by stuckinthemud1 Fri Dec 09, 2022 4:05 pm

» Fiberglass H-bows

by c sitas Sat Nov 12, 2022 8:44 am

» Bad Antler

by drawknife Sat Nov 12, 2022 3:48 am

» Anyone make their own bolts?

by Juniper Mon Oct 17, 2022 8:20 am

» Josef alm in English

by Juniper Sat Oct 15, 2022 4:22 am

» Qin/Han lock drawings

by kenh Fri Sep 23, 2022 8:16 pm

» stirrup dimensions?

by stuckinthemud1 Thu Sep 01, 2022 1:49 pm

» Skane/Lillohus lockbow information needed

by stuckinthemud1 Sun Aug 14, 2022 6:23 am

» need help contacting le musee Dauphinois Grenoble

by stuckinthemud1 Sat Aug 13, 2022 3:22 pm

+15

mac

Zardoz

kiwijim

Rizzar

panne

Lien93

Gnome

chaz

8fingers

Ivo

Basilisk120

Todd the archer

traxxas_slash7

stoneagebowyer

ferdinand

19 posters

Halbe rustung. Nearly finished now, next up is shooting it!!

ferdinand- Crossbow Junkie

I live here!

- Posts : 301

Join date : 2012-04-24

First steps towards a new build. Getting the angles correct on the parts to make it all work together whas kinda tricky. But i think it worked out. Next i have to clean them up and harden te surfaces to reduce wear, any ideas how to harden them? heating to redhot and cooling in oil sufficient? i made a short movie to show how it works. MAc, thanks for the picture of the 4 axel trigger assembly, i decided to keep it a bit simpler but it is basically the same.

Last edited by ferdinand on Fri Jan 25, 2013 8:24 am; edited 8 times in total

stoneagebowyer- Crossbow Junkie

I live here!

- Posts : 490

Join date : 2011-01-12

Well, interesting! I look forward to seeing your project develop. Dane

traxxas_slash7- Fresh Blood

Doesn't mean

I'm new to crossbows

- Posts : 10

Join date : 2012-04-21

Sweet. If its mild steel heat to non magnetic and quench in old motor oil for a little more carbon content. Be sure to use a respirator to avoid inhalation of carcinogens from the burnt oil.

Todd the archer- Crossbow Junkie

I live here!

- Posts : 581

Join date : 2010-02-25

Age : 62

Location : sellersville,pa.

Nice trigger Ferdinand, we seem to think the same. Except mine is a claplock and I added a set trigger mechanism.

I handened my sears by heating red hot and dip in suger. Like 4 times.

Good luck, Todd

I handened my sears by heating red hot and dip in suger. Like 4 times.

Good luck, Todd

Basilisk120- Moderator

- Posts : 548

Join date : 2010-03-01

Age : 45

Location : Arizona

That looks really good, actually both locks really really good.

But for case hardening or surface hardening. While an oil quench would do a little I think you would be better off looking for a surface hardening compound like "Cherry Red". Another product is Kasenit. I have heard sugar can work as well but I don't think it is as dependable or a good as the specialty products. Depending on what you have available for tools another technique is to pack the part to be hardened in to a ceramic or metal case filled with charcoal powder and let sit in the forge or other high temp fire for a long time.

The basic theory is that carbon move from the high concentration outside the metal into the low carbon area in the metal and that carbon moves through metal at a known speed (depending on temp).

But for case hardening or surface hardening. While an oil quench would do a little I think you would be better off looking for a surface hardening compound like "Cherry Red". Another product is Kasenit. I have heard sugar can work as well but I don't think it is as dependable or a good as the specialty products. Depending on what you have available for tools another technique is to pack the part to be hardened in to a ceramic or metal case filled with charcoal powder and let sit in the forge or other high temp fire for a long time.

The basic theory is that carbon move from the high concentration outside the metal into the low carbon area in the metal and that carbon moves through metal at a known speed (depending on temp).

ferdinand- Crossbow Junkie

I live here!

- Posts : 301

Join date : 2012-04-24

Thanks for the info, i will put them in a can with charcoal and put it in the campfire this weekend!Basilisk120 wrote:That looks really good, actually both locks really really good.

But for case hardening or surface hardening. While an oil quench would do a little I think you would be better off looking for a surface hardening compound like "Cherry Red". Another product is Kasenit. I have heard sugar can work as well but I don't think it is as dependable or a good as the specialty products. Depending on what you have available for tools another technique is to pack the part to be hardened in to a ceramic or metal case filled with charcoal powder and let sit in the forge or other high temp fire for a long time.

The basic theory is that carbon move from the high concentration outside the metal into the low carbon area in the metal and that carbon moves through metal at a known speed (depending on temp).

Coming sunday is our annual family shootout wich i organise, western theme this year so campfire is burning all day!!

Ivo- Admin

- Posts : 1041

Join date : 2009-11-25

Age : 36

Location : NJ, USA

Great work Ferdinand!

As they say ~ "The eyes are afraid, but the hands still do it"

Also, Case Hardening, is not that simple...not exactly simple to explain either, but simply placing the pieces into charcoal won't really do anything. You need an actual case hardening compound (can grab some from a gunsmith or online) or as Todd has mentioned sugar for a light case. Other things include cyanide salts (I think), but that's dangerous stuff...or packing parts tight into a pipe with leather and/or bone meal.

Really no expert on this, so I suggest you take a few minutes to research it.

Best of luck on this project.

Ivo

PS: Kasenit is no longer sold, Cherry Red is one of the few case hardening compounds left to public use.

As they say ~ "The eyes are afraid, but the hands still do it"

Also, Case Hardening, is not that simple...not exactly simple to explain either, but simply placing the pieces into charcoal won't really do anything. You need an actual case hardening compound (can grab some from a gunsmith or online) or as Todd has mentioned sugar for a light case. Other things include cyanide salts (I think), but that's dangerous stuff...or packing parts tight into a pipe with leather and/or bone meal.

Really no expert on this, so I suggest you take a few minutes to research it.

Best of luck on this project.

Ivo

PS: Kasenit is no longer sold, Cherry Red is one of the few case hardening compounds left to public use.

8fingers- Workshop Savvy

Did you see my tool collection?

- Posts : 200

Join date : 2011-04-06

Location : Chetwynd, BC, Canada

For color case hardening you need to heat in a carbon medium ( leather scraps, charcoal, sugar) in a closed vessel (try mini flower pots, sealed with clay) then dump the parts into a salt peter brine, with air being pumped through it vigorously. Big bicycle pump with a strong,motivated assistant would be a minimum, if you brine tank was smallish. More air yields better color.

A source of salt peter is instant cold packs with ammonium nitrate on the label. I don't remember the concentration required but I'll check my library. Try one cold pack in 3-4 gallons of water.

Don't reuse the sediment as it is 2/3s gunpowder and needs to be disposed of responsibly.

Don't reuse the sediment as it is 2/3s gunpowder and needs to be disposed of responsibly.  Maybe throwing small handfuls of damp sediment on a campfire. Ever hear the one about the fellow who burned down the old out house next to the party Grotto? Looked like a nuke had gone off. Damp, small handfuls please.

Maybe throwing small handfuls of damp sediment on a campfire. Ever hear the one about the fellow who burned down the old out house next to the party Grotto? Looked like a nuke had gone off. Damp, small handfuls please.

A source of salt peter is instant cold packs with ammonium nitrate on the label. I don't remember the concentration required but I'll check my library. Try one cold pack in 3-4 gallons of water.

Don't reuse the sediment as it is 2/3s gunpowder and needs to be disposed of responsibly.

Don't reuse the sediment as it is 2/3s gunpowder and needs to be disposed of responsibly.  Maybe throwing small handfuls of damp sediment on a campfire. Ever hear the one about the fellow who burned down the old out house next to the party Grotto? Looked like a nuke had gone off. Damp, small handfuls please.

Maybe throwing small handfuls of damp sediment on a campfire. Ever hear the one about the fellow who burned down the old out house next to the party Grotto? Looked like a nuke had gone off. Damp, small handfuls please.

ferdinand- Crossbow Junkie

I live here!

- Posts : 301

Join date : 2012-04-24

Thanks again guys!!

8fingers, thanks for the hints and tips but i prefer to be keep 10fingers:bom:

The cherry red sounds really good, ill try to get a hold of some of that stuff. Chemicals like that are hard to come by in the Netherlands because not many people practise hand skills like this anymore. But for now, i have my hands full with the washing machine bearings that are busted. And as an little "thank u" the dryer started to leak water at the same time.......

I'll post when i have made any progress, i still wonder if i should make a trigger assembly that i can put into the tiller as a whole. Maybe the wood is to sof to support the axels?

8fingers, thanks for the hints and tips but i prefer to be keep 10fingers:bom:

The cherry red sounds really good, ill try to get a hold of some of that stuff. Chemicals like that are hard to come by in the Netherlands because not many people practise hand skills like this anymore. But for now, i have my hands full with the washing machine bearings that are busted. And as an little "thank u" the dryer started to leak water at the same time.......

I'll post when i have made any progress, i still wonder if i should make a trigger assembly that i can put into the tiller as a whole. Maybe the wood is to sof to support the axels?

ferdinand- Crossbow Junkie

I live here!

- Posts : 301

Join date : 2012-04-24

Tiller construction is on the way! I had an aged peace of Azobé tropical hardwood in the backyard for a couple of years wich i am now converting into a tiller.

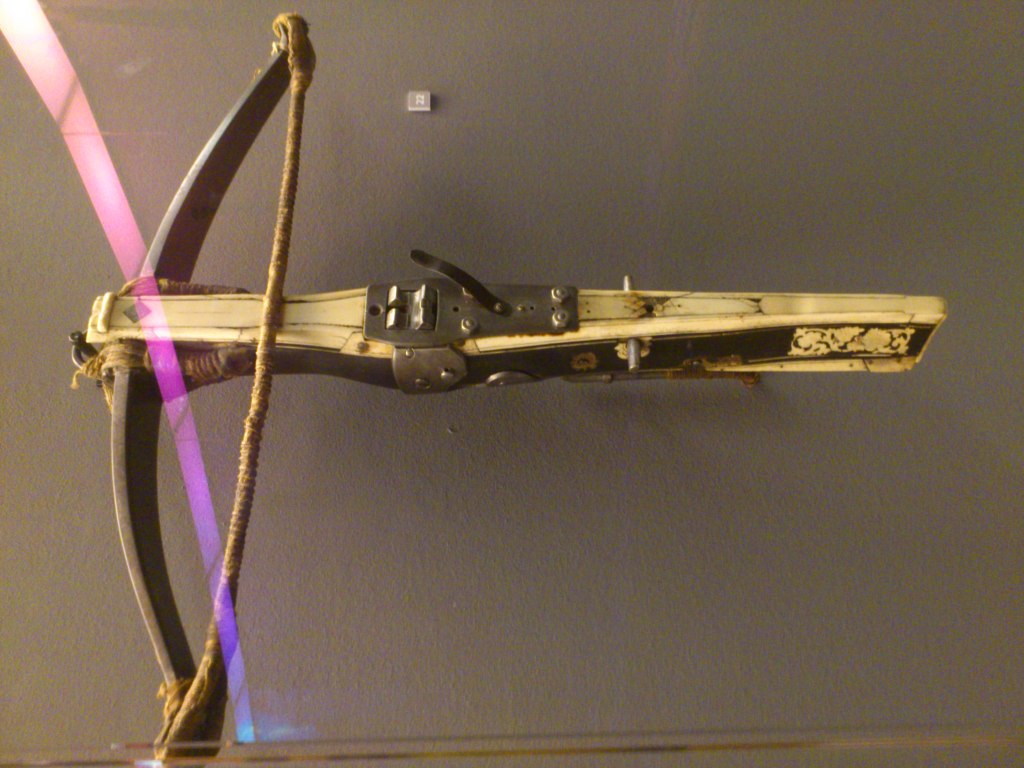

Tiller construction is on the way! I had an aged peace of Azobé tropical hardwood in the backyard for a couple of years wich i am now converting into a tiller.If all goes as planned i will make a replica of the bow in the Royal Dutch Army Museum inventory number: 12012 , a German schnepper dated 1725 as shown above.

I probably wont be able to get the bone or horn inlay and detail of decorations correct but i will focus on the metalwork. Any ideas for imitation bone are welcome.

chaz- Crossbow Junkie

I live here!

- Posts : 313

Join date : 2012-04-13

Age : 75

Location : Texas

Ferdi,

How about using Formica (brand name) Wilson Art is another brand name for pretty nuch the same thing, a laminate material used for countertops? I believe it comes in a bone color. Applies with contact cement Might also be used for inlays. Just a thought. Actually comes in various colors.

Chaz

How about using Formica (brand name) Wilson Art is another brand name for pretty nuch the same thing, a laminate material used for countertops? I believe it comes in a bone color. Applies with contact cement Might also be used for inlays. Just a thought. Actually comes in various colors.

Chaz

ferdinand- Crossbow Junkie

I live here!

- Posts : 301

Join date : 2012-04-24

Thanks chaz, the formica sounds great, i can make little plates to mimic real bone/horn inlay wich i can glue and nail to the stock.chaz wrote:Ferdi,

How about using Formica (brand name) Wilson Art is another brand name for pretty nuch the same thing, a laminate material used for countertops? I believe it comes in a bone color. Applies with contact cement Might also be used for inlays. Just a thought. Actually comes in various colors.

Chaz

chaz- Crossbow Junkie

I live here!

- Posts : 313

Join date : 2012-04-13

Age : 75

Location : Texas

Ferdi,

You are welcome. Both brands have web-sites with color charts. Wilsonart is one word. Hope this will be helpful.

Chaz

You are welcome. Both brands have web-sites with color charts. Wilsonart is one word. Hope this will be helpful.

Chaz

Ivo- Admin

- Posts : 1041

Join date : 2009-11-25

Age : 36

Location : NJ, USA

ferdinand wrote:i still wonder if i should make a trigger assembly that i can put into

the tiller as a whole. Maybe the wood is to sof to support the axels?

I'm on the same frequency as you Ferdinand.

I have a few thoughts on the idea, wish I had drawn something up to make the explanation easier, but words are all I got for now.

So the idea is from an Airgun trigger mech discussed here > Link

And is basically side plates with some spacers (or bent sheet metal box), tubes pressed into the housing serving as hollow axels that hold the components in the housing. After the installation of this assembly into the tiller/stock, *actual* axel rods are pressed through the stock and the hollow tube axels. Cool thought comes to mind - taking advantage of the hollow axel tubes as drill guides.

Think this way, by binding everything together into a one piece mechanism, we should be able to distribute the load a little better and possibly prevent many shifts in the system that are most likely unavoidable with wood alone......

Personally when I first started researching this bow, I actually thought that a solid assembly inletted into the tiller was exactly how they did it in the past.

~ Imagine my surprise when I found out it was all riveted in wood alone.

Ivo

Todd the archer- Crossbow Junkie

I live here!

- Posts : 581

Join date : 2010-02-25

Age : 62

Location : sellersville,pa.

Ferdinand and Ivo, that is close to what I did with my build. If you go back and look at the picture of my lock you can see one of the two side plates (made from a circular sawblade). The logic was twofold; keeps the geometry and interaction of the parts in precise alignment. I think I said before it is kind of like a swiss watch. Secondly it provides more strength as the load is spread out to the other axles as a unit, particulary on mine the claplock axle is near the edges of the wood stock. I did not use hollow tubes as Ivo suggested but merely use the plate as a drill guide on the stock then inserted the plates and parts inside then tapped in long axles with a point ground on one end until coming through both sides then trimmed flush. Should mention my axles are all 1/8" hardened "axle" rod from Lowes.

Todd

Todd

chaz- Crossbow Junkie

I live here!

- Posts : 313

Join date : 2012-04-13

Age : 75

Location : Texas

Ferdi

You might check out : Wilsonart: Antique white 1572 SL, Natural Almond D30 SL

Formica: Sail White Oxide 300, Almond 920, Antique White Oxide 303, Antique White Papercraft 303

These colors seem to appear like bone.

Chaz

You might check out : Wilsonart: Antique white 1572 SL, Natural Almond D30 SL

Formica: Sail White Oxide 300, Almond 920, Antique White Oxide 303, Antique White Papercraft 303

These colors seem to appear like bone.

Chaz

ferdinand- Crossbow Junkie

I live here!

- Posts : 301

Join date : 2012-04-24

Thanks for the great advice guys! But its really hard to get this in europe. I am thinking about ordering it from the states or one other option: I have a domino set wich is imitation ivory. The only thing is that i will have short peaces with all the same lengt( i could change that to make authentic look). What do u think guys, domino's have great colour?

Thanks for the great advice guys! But its really hard to get this in europe. I am thinking about ordering it from the states or one other option: I have a domino set wich is imitation ivory. The only thing is that i will have short peaces with all the same lengt( i could change that to make authentic look). What do u think guys, domino's have great colour?Here are some pics of my tiller in construction, hard work with hardwood.

ferdinand- Crossbow Junkie

I live here!

- Posts : 301

Join date : 2012-04-24

Top picture shows the tiller roughly rounded off. Second picture is the trigger with a spring made of a 0.75 feeler gauge. Third shows the trigger assembly in place with all the axle's and the nut socket cut out. Next i will probably sand it roughly and decide how to put in the ivory. To be continued...

ferdinand- Crossbow Junkie

I live here!

- Posts : 301

Join date : 2012-04-24

Sweeeeet! 3 domino's and 15 minutes. Contact adhesive, really strong!

This works, isnt that just nice for under 4 bucks.

This works, isnt that just nice for under 4 bucks.

ferdinand- Crossbow Junkie

I live here!

- Posts : 301

Join date : 2012-04-24

Wow, how enthousiastic i whas.......

Wow, how enthousiastic i whas.......This is some serious hard labour!

But i'm gettin there i think, the results are good enough for me.

After i finish covering the whole top of the prod an making the cheek-rest i will get to "aging" the stuff, but thats a different topic running allready.

Now the results so far, made it a bit wet to see the colour of the wood better.

stoneagebowyer- Crossbow Junkie

I live here!

- Posts : 490

Join date : 2011-01-12

Looking great! My question to you is how you determined where to drill exactly for the various axles. Did you create some sort of pattern after getting the layout of the trigger parts and use that as a guide to drilling the holes? Being off even by a tiny amount could make the trigger useless. If you can share, I'd love to hear how you did it.

Dane

Dane

Todd the archer- Crossbow Junkie

I live here!

- Posts : 581

Join date : 2010-02-25

Age : 62

Location : sellersville,pa.

Would also like to hear how Ferdinand did it.Read post no. 15 for how I did mine.

Really like how your deck came out as well/

Todd

Really like how your deck came out as well/

Todd

ferdinand- Crossbow Junkie

I live here!

- Posts : 301

Join date : 2012-04-24

stoneagebowyer wrote:Looking great! My question to you is how you determined where to drill exactly for the various axles. Did you create some sort of pattern after getting the layout of the trigger parts and use that as a guide to drilling the holes? Being off even by a tiny amount could make the trigger useless. If you can share, I'd love to hear how you did it.

Dane

Hey Dane!

Making the holes correct whas no easy thing to do!

First i put them on a thin peace of wood and marked out each hole individually by testing if the components work after putting on the next peace.

First hole is easy, just drill it.

Second part i put on and use a drill for wood as axle because it has a little sharp point.

Then if the function i make the hole wich is,allready centred by the drill.

And then the next and next.

Put bolts in and test.

Adjusting length of a part is easy, hammer it out a bit before case hardenjng, shorten with file.

I used that peace of wood ( u can see it in the little film) asa mold.

Again using the drill for wood to first mark out the centers by hand wiyh the Sharp point.

The tiller whad still square when i drilled the holes thru snd thru.

That whas a risk, maybe a fixxed trigger assembly is easier.

I used 6mm cold milled steel rod for axles. And hardened the parts with sugar as a firtst test how it holds up!

Hope this answers the question?

Dunno if this is the easiest way but it works for me!

stoneagebowyer- Crossbow Junkie

I live here!

- Posts : 490

Join date : 2011-01-12

Great description. I am designing a two axel trigger right now, and your method sounds very workable. Thank you!

ferdinand- Crossbow Junkie

I live here!

- Posts : 301

Join date : 2012-04-24

No thanks.stoneagebowyer wrote:Great description. I am designing a two axel trigger right now, and your method sounds very workable. Thank you!

Anyway, if u are not sure of the accuracy of the holes, oversize ur parts!!

Quick question to u, can Larix wood be used for a 2meter longbow?

Private messages

Private messages