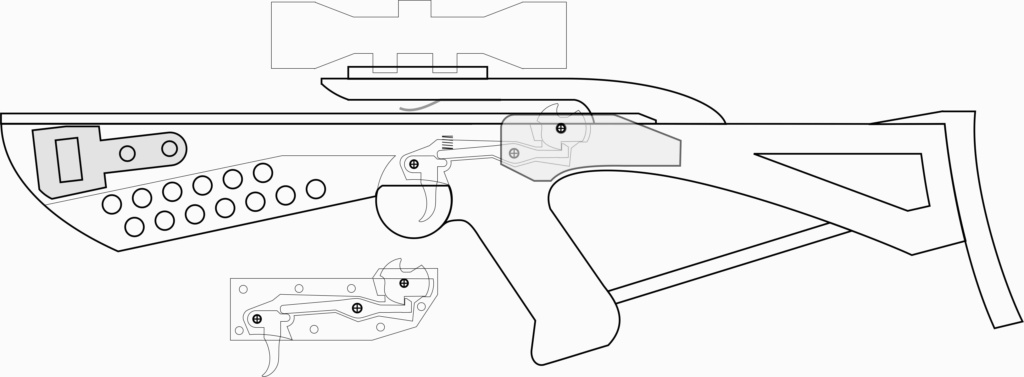

So I am an absolute beginner crossbow builder, but I have some wood working and bowyering experience as well as decently fitted out little wood shop in my basement. I think this is gorgeous and is what I'd like to try to build:

Am I out of my gourd? I think I'm at the reach of my abilities here... The parts where I have real concerns are the trigger mechanism (more on that in minute) and mounting the prod.

I am starting to gather materials and draw out plans. So far I have red oak for the stock and some steel banding to replicate the mounting plate as seen in the picture above.

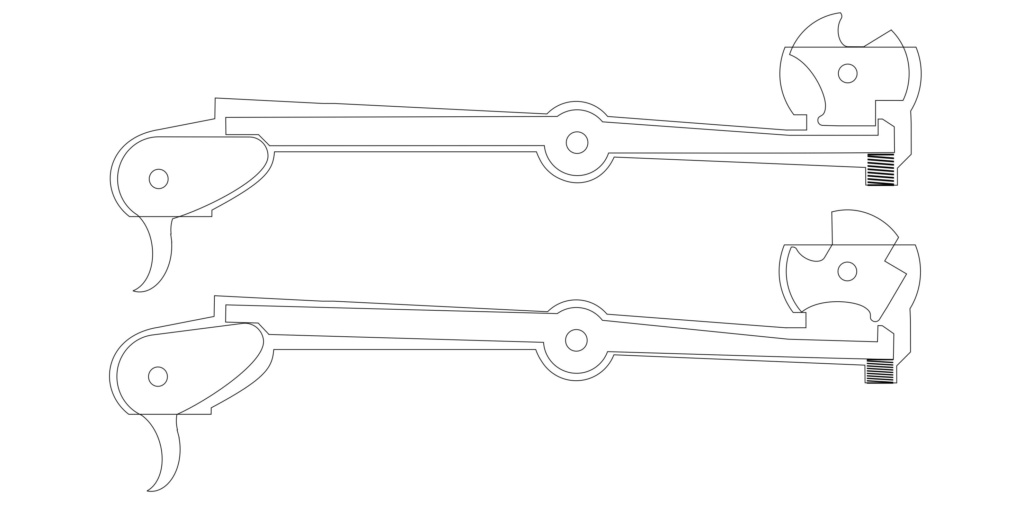

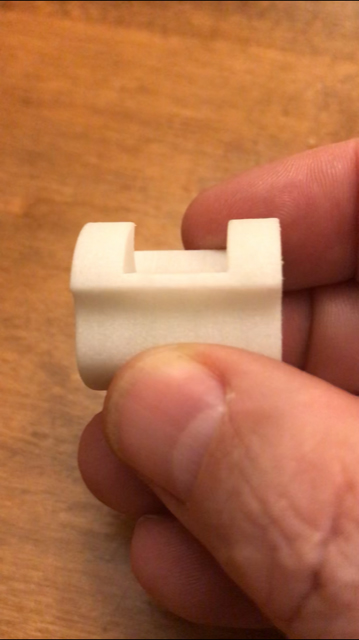

I am going to keep this fairly low draw weight at between 80 and 100 lbs and was wondering if delrin would be strong enough to make a nut from. Never having worked with it before, I'm not sure of its limitations.

The trigger/cam would be delrin, the lever steel, the nut delrin. All critiques are welcomed on this as I'm really not sure what I'm doing, lol.

The prod I'm considering would either be a manufactured one like on the crossbow pictured or using the tips of cross country skis to make my own. I'm not 100% how the prod is held in place in the photo, or in the series of photos this pic is taken from. Anyone have any guesses? Thanks in advance for any and all help!

Private messages

Private messages