Latest topics

» What you building?

by hullutiedemies Tue Jul 09, 2024 12:39 am

» 12th Century Chinese Crossbow Chronographed

by stuckinthemud1 Fri Nov 24, 2023 3:50 pm

» Crossbow Stock

by kenh Tue Oct 31, 2023 6:19 am

» Colletiere a Charavines continuing experiment

by stuckinthemud1 Sat Oct 07, 2023 5:36 am

» Cocking - how

by stuckinthemud1 Thu Aug 03, 2023 4:24 am

» Questions around heavy crossbow lath buildin

by stuckinthemud1 Wed Apr 26, 2023 1:10 am

» Arab Crossbow

by stuckinthemud1 Tue Apr 25, 2023 7:57 am

» prod angle, and lever trigger for sale anyone?

by stuckinthemud1 Mon Mar 20, 2023 5:54 am

» flexible string

by jasper1978 Mon Mar 20, 2023 1:25 am

» [solved]Skane/Lillohus crossbow thread

by stuckinthemud1 Sun Mar 19, 2023 7:44 am

» jens sensfelder

by jasper1978 Wed Mar 08, 2023 11:58 pm

» 400lb Windlass crossbow bolts weight and accuracy shooting high.

by stuckinthemud1 Sun Mar 05, 2023 2:53 pm

» Codex Löffelholz crossbow

by stuckinthemud1 Tue Jan 24, 2023 4:14 pm

» Digitar prodsc

by stuckinthemud1 Sun Jan 15, 2023 2:42 pm

» Troubleshooting

by Andy. Fri Jan 06, 2023 12:29 pm

» Wood Prods

by stuckinthemud1 Fri Dec 30, 2022 12:47 pm

» Colletiere a Charavines crossbow

by stuckinthemud1 Fri Dec 30, 2022 8:54 am

» Simplified Löffelhotz speedloader

by stuckinthemud1 Fri Dec 09, 2022 4:05 pm

» Fiberglass H-bows

by c sitas Sat Nov 12, 2022 8:44 am

» Bad Antler

by drawknife Sat Nov 12, 2022 3:48 am

» Anyone make their own bolts?

by Juniper Mon Oct 17, 2022 8:20 am

» Josef alm in English

by Juniper Sat Oct 15, 2022 4:22 am

» Qin/Han lock drawings

by kenh Fri Sep 23, 2022 8:16 pm

» stirrup dimensions?

by stuckinthemud1 Thu Sep 01, 2022 1:49 pm

» Skane/Lillohus lockbow information needed

by stuckinthemud1 Sun Aug 14, 2022 6:23 am

by hullutiedemies Tue Jul 09, 2024 12:39 am

» 12th Century Chinese Crossbow Chronographed

by stuckinthemud1 Fri Nov 24, 2023 3:50 pm

» Crossbow Stock

by kenh Tue Oct 31, 2023 6:19 am

» Colletiere a Charavines continuing experiment

by stuckinthemud1 Sat Oct 07, 2023 5:36 am

» Cocking - how

by stuckinthemud1 Thu Aug 03, 2023 4:24 am

» Questions around heavy crossbow lath buildin

by stuckinthemud1 Wed Apr 26, 2023 1:10 am

» Arab Crossbow

by stuckinthemud1 Tue Apr 25, 2023 7:57 am

» prod angle, and lever trigger for sale anyone?

by stuckinthemud1 Mon Mar 20, 2023 5:54 am

» flexible string

by jasper1978 Mon Mar 20, 2023 1:25 am

» [solved]Skane/Lillohus crossbow thread

by stuckinthemud1 Sun Mar 19, 2023 7:44 am

» jens sensfelder

by jasper1978 Wed Mar 08, 2023 11:58 pm

» 400lb Windlass crossbow bolts weight and accuracy shooting high.

by stuckinthemud1 Sun Mar 05, 2023 2:53 pm

» Codex Löffelholz crossbow

by stuckinthemud1 Tue Jan 24, 2023 4:14 pm

» Digitar prodsc

by stuckinthemud1 Sun Jan 15, 2023 2:42 pm

» Troubleshooting

by Andy. Fri Jan 06, 2023 12:29 pm

» Wood Prods

by stuckinthemud1 Fri Dec 30, 2022 12:47 pm

» Colletiere a Charavines crossbow

by stuckinthemud1 Fri Dec 30, 2022 8:54 am

» Simplified Löffelhotz speedloader

by stuckinthemud1 Fri Dec 09, 2022 4:05 pm

» Fiberglass H-bows

by c sitas Sat Nov 12, 2022 8:44 am

» Bad Antler

by drawknife Sat Nov 12, 2022 3:48 am

» Anyone make their own bolts?

by Juniper Mon Oct 17, 2022 8:20 am

» Josef alm in English

by Juniper Sat Oct 15, 2022 4:22 am

» Qin/Han lock drawings

by kenh Fri Sep 23, 2022 8:16 pm

» stirrup dimensions?

by stuckinthemud1 Thu Sep 01, 2022 1:49 pm

» Skane/Lillohus lockbow information needed

by stuckinthemud1 Sun Aug 14, 2022 6:23 am

5 posters

First Build

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°1

First Build

First Build

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°2

Re: First Build

Re: First Build

This is a crossbow build I am working on for my friend the bow is made out of rattan a type of palm, the stock will be made out of red oak. I don't have all the parts yet such as the roller nut but I do have 3/16" mild steel plate for the trigger. The prod is 25" inches long it is approximately 36 lbs @ 10". It is 1 5/16" wide at the center of the prod for 2.5" on each side of the center of the prod. A problem I have been having is when my friend cut the manau rattan stave in half lengthwise he accidentally made a mistake. As you can see in one of the pictures where it shows the center belly of the prod he accidentally cut into it a bit and it created a slight hinge. Most of that side of the prod where he accidentally cut into the belly it doesn't bend as much as it does where he had cut. So I was wondering what to do to fix it I thought of tapering the prod more so instead of the center being full width for 5 inches of the center of the prod. I would maybe make it so it would taper as soon as it extends from the width of the stock of the crossbow. So that would be 1.5" it would be full width at that point so 3/4" on both sides of the center of the prod. Another thing I thought of was if the corners of the prod seem to sharp I would round them off. Not only would this prevent splinters from rising it would also make the prod bend more at stiff spots. I also thought of maybe piking the prod to increase draw weight so it would be 22" long instead of 25". I might even try to debark it then back it with raw hide to increase the draw weight as well. Any comments and suggestions are welcome.

P.S. I also tried firing hardening the belly of the prod to see it would increase the draw weight and or reduce string follow.

P.S. I also tried firing hardening the belly of the prod to see it would increase the draw weight and or reduce string follow.

kenh- Crossbow Junkie

I live here!

- Posts : 884

Join date : 2012-08-03

Age : 76

Location : Living Aboard a Sailboat in Fort Myers, FL

- Post n°3

Re: First Build

Re: First Build

Rawhide backing will NOT increase the draw weight at all. Only sinew will do that. Other backings help prevent splinters, that's all.

I'm not sure whether rattan is worth messing with as a prod material. I've seen it used for vertical bows, but they are all in excess of 4 ft from tip to tip. Bamboo as a prod -- yes -- flat laths stacked together to manipulate draw weight is ancient Chinese crossbow technology.

I'm not sure whether rattan is worth messing with as a prod material. I've seen it used for vertical bows, but they are all in excess of 4 ft from tip to tip. Bamboo as a prod -- yes -- flat laths stacked together to manipulate draw weight is ancient Chinese crossbow technology.

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°4

Re: First Build

Re: First Build

I just wanted to make a light target crossbow for my friend. The good thing about rattan is it's very flexible and durable. I chose it as the prod material because I saw a guy used it for his crossbow. Not only that but I have used it before for a bow.

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°5

Re: First Build

Re: First Build

How long should the center of the prod be full width? Should it be just as long as the width of the stock or the crossbow or longer? Also should I pike the prod 3" to compensate for making the taper of the limbs longer so it will make the draw weight higher than if I just left it as is?

stuckinthemud1- Crossbow Junkie

I live here!

- Posts : 527

Join date : 2014-02-05

Age : 56

Location : south wales valleys

- Post n°6

Re: First Build

Re: First Build

I think that you should cut in some temporary nocks as soon as you can and get it onto the tillering tree. Most of these questions will resolve themselves as you tiller. I found that wooden prods work very much like full-size bows, but they are more stoutly built, suggest you initially try keeping the centre few inchesas non-bending to avoid the stock corners digging into the rattan then constant taper to the tips reducing height by 1/3 at the tips and by about 1mm per inch of thickness. The hinge must be tillered out or the prod will fail

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°7

Re: First Build

Re: First Build

The prod is 1 5/16" wide at the center I did the math so that would mean it has to be 7/8" wide at the tips but what did you mean by "1mm per inch of thickness"? The prod I think is 1/2" wide at the tips because I removed a lot of wood trying to get rid of that hinge. Also trying to make it bend more towards the tips rather than at the center.

stuckinthemud1- Crossbow Junkie

I live here!

- Posts : 527

Join date : 2014-02-05

Age : 56

Location : south wales valleys

- Post n°8

Re: First Build

Re: First Build

Seems from what you say your best bet is to start tillering and see where you are, that is certainly what I would do next

stuckinthemud1- Crossbow Junkie

I live here!

- Posts : 527

Join date : 2014-02-05

Age : 56

Location : south wales valleys

- Post n°9

Re: First Build

Re: First Build

The last prod I made I reduced in thickness by 1mm for every 1 inch away from the stiff zone at the centre, so if each limb was 10 inches long, the tips would be 9mm thinner than the thickness at centre but the yew I used wont behave like your rattan

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°10

Re: First Build

Re: First Build

Okay thank you very much, that explains it.

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°11

Re: First Build

Re: First Build

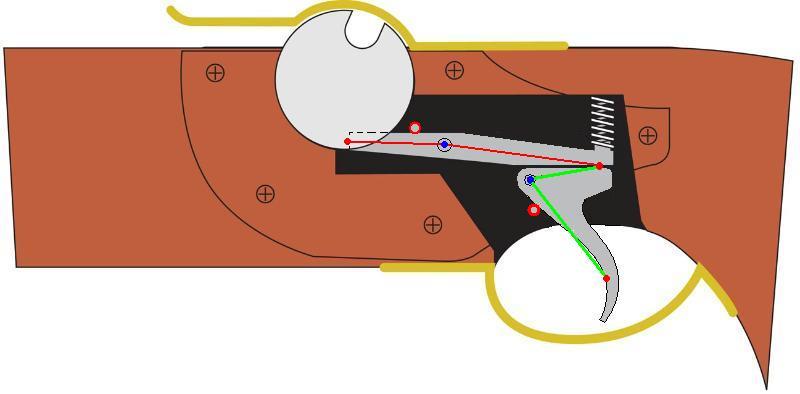

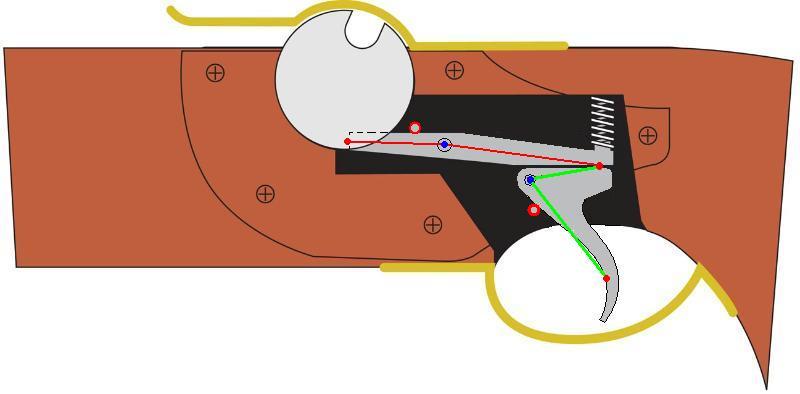

I'm going to string up and work on the prod tomorrow. I wanted to share the design of the trigger mechanism I am going to use. By no means is this my design, I found it on this forum. It was by Ivo on one of Gnome's post. I was wondering how can I print this to scale? I don't really have any special equipment or anything like that.

Geezer- Master Crossbowyer

- Posts : 1194

Join date : 2010-01-12

Age : 76

Location : Austin, Texas, USA

- Post n°12

Re: First Build

Re: First Build

Good choice: that should work very well. Geezer.

\

\

stuckinthemud1- Crossbow Junkie

I live here!

- Posts : 527

Join date : 2014-02-05

Age : 56

Location : south wales valleys

- Post n°13

Re: First Build

Re: First Build

I usually print stuff off and mess about with resizing on the photocopier, but simple designs are easier and quicker to draw out with compasses and rules

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°14

Re: First Build

Re: First Build

Okay thank you very much for the advice, I am going to make the string out of hemp twine. The bow is a pretty light draw weight, it will probably get lower since I have to finish tillering it. Right now, it is about 36 lbs @ 10." The twine I'll be using once I get it looks pretty thin. The friend I am making this for has a deformed hand would you guys have any ideas what I could make as a cocking aid so he can load the crossbow? He said he would be fine with just a stirrup but I am not sure he is going to be able to load it.

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°15

Re: First Build

Re: First Build

Finally got the prod strung up. I noticed that it is bending more in the middle of the bottom limb, and upper limb looks stiffer. There is a slight dip if you can notice in the upper half of the mid section. That is where my friend had accidentally cut into the belly of the prod when sawing the stave in half. I was trying to get the prod to bend away from that area so a hinge wouldn't form. But, unfortunately I think I had overcompensated by making the bottom limb bend more. Any help or advice would be greatly appreciated.

stuckinthemud1- Crossbow Junkie

I live here!

- Posts : 527

Join date : 2014-02-05

Age : 56

Location : south wales valleys

- Post n°16

Re: First Build

Re: First Build

I think your assessment is correct, you need to soften the top limb to match the other, but take things really slowly. If the nick is not affecting anything then just keep an eye on it while you work on the bow but be prepared that you may need to thin the whole bow to get rid of it. Alternately glue in a tiny patch (thats what I would do)

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°17

Re: First Build

Re: First Build

What do you guys think of fire hardening/heat treating the belly of the prod? I did this with my prod, but on one of the limbs I have to take off wood so I probably have to heat treat it again.

stuckinthemud1- Crossbow Junkie

I live here!

- Posts : 527

Join date : 2014-02-05

Age : 56

Location : south wales valleys

- Post n°18

Re: First Build

Re: First Build

Possibly. If you did the heat treat right it will have soaked through most of the thickness of the prod so no need to redo it. If you werent that thorough - the back of the prod should be feeling warm to hot as the heat soaks right rhrough from the belly- then it might be worth having another go. Changing colour of the belly is not a good way to judge the process.

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°19

Re: First Build

Re: First Build

I heated treated the prod because I was trying to see if I could get any increase in draw weight. Heat treating makes the prod more stiffer and the belly of the prod harder. Today I am going to tiller the prod, and try to make both of the limbs bend evenly. Once I am done I will show pictures of the results. I possibly might just reheat/fire harden the part of the limb where I took off wood to make both of them look even.

stuckinthemud1- Crossbow Junkie

I live here!

- Posts : 527

Join date : 2014-02-05

Age : 56

Location : south wales valleys

- Post n°20

Re: First Build

Re: First Build

Look forward to seeing the pics.

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°21

Re: First Build

Re: First Build

I just got done with retillering my prod by taking wood off the limb that was stiff(the right limb in the picture.)

Last edited by banuvatt on Fri Dec 13, 2019 3:59 pm; edited 2 times in total

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°22

Re: First Build

Re: First Build

I would like to see what you guys think. Does my prod look evenly tillered or does one limb still look like it is bending more than the other? I frankly am kind of having a hard time telling whether if both of the limbs are bending evenly.

stuckinthemud1- Crossbow Junkie

I live here!

- Posts : 527

Join date : 2014-02-05

Age : 56

Location : south wales valleys

- Post n°23

Re: First Build

Re: First Build

I held a dish up to the computer screen and the curve of the prod matched the arc of the dish-rim so I think they are bending pretty evenly although the right one looks a tiny bit more stiff than the left. Not sure but the centre looks like it is bending more than then limbs so there could be a potential for trouble there you need to keep an eye on. The limb tips only need to move a couple of inches from here to give you full draw so you're nearly done. Keep doing what you're doing, its coming on nicely

banuvatt- Workshop Savvy

Did you see my tool collection?

- Posts : 271

Join date : 2018-09-12

- Post n°24

Re: First Build

Re: First Build

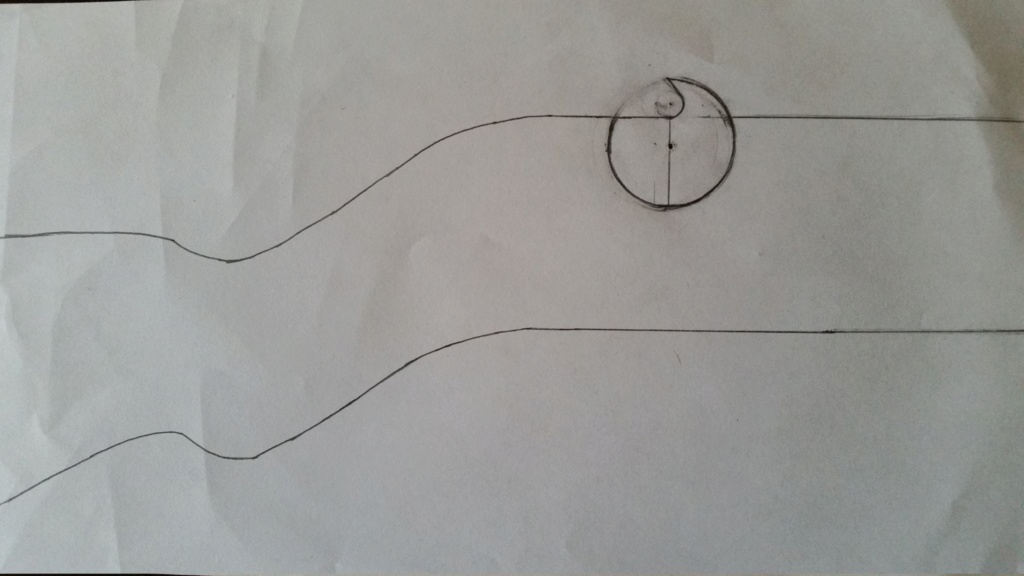

Thank you, I just got started with trying to draw out the plans for the trigger mechanism. I am just wondering does this look like enough room for the trigger mechanism? When I had cut out the stock for the crossbow I think I accidentally underestimated how long it actually had to be. To accommodate not only for the front of the stock and the prod''s draw length, but also room for the trigger mechanism.

Thank you, I just got started with trying to draw out the plans for the trigger mechanism. I am just wondering does this look like enough room for the trigger mechanism? When I had cut out the stock for the crossbow I think I accidentally underestimated how long it actually had to be. To accommodate not only for the front of the stock and the prod''s draw length, but also room for the trigger mechanism.

stuckinthemud1- Crossbow Junkie

I live here!

- Posts : 527

Join date : 2014-02-05

Age : 56

Location : south wales valleys

- Post n°25

Re: First Build

Re: First Build

Dont be tied by plans, with wooden prod based crossbows, the draw length of the finished bow decides where the mechanism goes. I learned this the hard way. Finish the prod and decide on the optimum draw length then build the tiller. I only make early medieval type bows so I am afraid I cannot advise on other types of mechanism

Private messages

Private messages