Paul

Latest topics

» [solved]Skane/Lillohus crossbow thread

by stuckinthemud1 Sat Aug 10, 2024 3:16 pm

» Colletiere a Charavines continuing experiment

by stuckinthemud1 Fri Aug 02, 2024 7:13 am

» What you building?

by hullutiedemies Tue Jul 09, 2024 12:39 am

» 12th Century Chinese Crossbow Chronographed

by stuckinthemud1 Fri Nov 24, 2023 3:50 pm

» Crossbow Stock

by kenh Tue Oct 31, 2023 6:19 am

» Cocking - how

by stuckinthemud1 Thu Aug 03, 2023 4:24 am

» Questions around heavy crossbow lath buildin

by stuckinthemud1 Wed Apr 26, 2023 1:10 am

» Arab Crossbow

by stuckinthemud1 Tue Apr 25, 2023 7:57 am

» prod angle, and lever trigger for sale anyone?

by stuckinthemud1 Mon Mar 20, 2023 5:54 am

» flexible string

by jasper1978 Mon Mar 20, 2023 1:25 am

» jens sensfelder

by jasper1978 Wed Mar 08, 2023 11:58 pm

» 400lb Windlass crossbow bolts weight and accuracy shooting high.

by stuckinthemud1 Sun Mar 05, 2023 2:53 pm

» Codex Löffelholz crossbow

by stuckinthemud1 Tue Jan 24, 2023 4:14 pm

» Digitar prodsc

by stuckinthemud1 Sun Jan 15, 2023 2:42 pm

» Troubleshooting

by Andy. Fri Jan 06, 2023 12:29 pm

» Wood Prods

by stuckinthemud1 Fri Dec 30, 2022 12:47 pm

» Colletiere a Charavines crossbow

by stuckinthemud1 Fri Dec 30, 2022 8:54 am

» Simplified Löffelhotz speedloader

by stuckinthemud1 Fri Dec 09, 2022 4:05 pm

» Fiberglass H-bows

by c sitas Sat Nov 12, 2022 8:44 am

» Bad Antler

by drawknife Sat Nov 12, 2022 3:48 am

» Anyone make their own bolts?

by Juniper Mon Oct 17, 2022 8:20 am

» Josef alm in English

by Juniper Sat Oct 15, 2022 4:22 am

» Qin/Han lock drawings

by kenh Fri Sep 23, 2022 8:16 pm

» stirrup dimensions?

by stuckinthemud1 Thu Sep 01, 2022 1:49 pm

» Skane/Lillohus lockbow information needed

by stuckinthemud1 Sun Aug 14, 2022 6:23 am

by stuckinthemud1 Sat Aug 10, 2024 3:16 pm

» Colletiere a Charavines continuing experiment

by stuckinthemud1 Fri Aug 02, 2024 7:13 am

» What you building?

by hullutiedemies Tue Jul 09, 2024 12:39 am

» 12th Century Chinese Crossbow Chronographed

by stuckinthemud1 Fri Nov 24, 2023 3:50 pm

» Crossbow Stock

by kenh Tue Oct 31, 2023 6:19 am

» Cocking - how

by stuckinthemud1 Thu Aug 03, 2023 4:24 am

» Questions around heavy crossbow lath buildin

by stuckinthemud1 Wed Apr 26, 2023 1:10 am

» Arab Crossbow

by stuckinthemud1 Tue Apr 25, 2023 7:57 am

» prod angle, and lever trigger for sale anyone?

by stuckinthemud1 Mon Mar 20, 2023 5:54 am

» flexible string

by jasper1978 Mon Mar 20, 2023 1:25 am

» jens sensfelder

by jasper1978 Wed Mar 08, 2023 11:58 pm

» 400lb Windlass crossbow bolts weight and accuracy shooting high.

by stuckinthemud1 Sun Mar 05, 2023 2:53 pm

» Codex Löffelholz crossbow

by stuckinthemud1 Tue Jan 24, 2023 4:14 pm

» Digitar prodsc

by stuckinthemud1 Sun Jan 15, 2023 2:42 pm

» Troubleshooting

by Andy. Fri Jan 06, 2023 12:29 pm

» Wood Prods

by stuckinthemud1 Fri Dec 30, 2022 12:47 pm

» Colletiere a Charavines crossbow

by stuckinthemud1 Fri Dec 30, 2022 8:54 am

» Simplified Löffelhotz speedloader

by stuckinthemud1 Fri Dec 09, 2022 4:05 pm

» Fiberglass H-bows

by c sitas Sat Nov 12, 2022 8:44 am

» Bad Antler

by drawknife Sat Nov 12, 2022 3:48 am

» Anyone make their own bolts?

by Juniper Mon Oct 17, 2022 8:20 am

» Josef alm in English

by Juniper Sat Oct 15, 2022 4:22 am

» Qin/Han lock drawings

by kenh Fri Sep 23, 2022 8:16 pm

» stirrup dimensions?

by stuckinthemud1 Thu Sep 01, 2022 1:49 pm

» Skane/Lillohus lockbow information needed

by stuckinthemud1 Sun Aug 14, 2022 6:23 am

+4

Ivo

Geezer

genesis

Archer46176

8 posters

I am back with new project

Archer46176- Fresh Blood

Doesn't mean

I'm new to crossbows

- Posts : 44

Join date : 2011-04-19

- Post n°1

I am back with new project

I am back with new project

Decided to scrap the medievel style bow project before it really even got started. I ordered a brand new Horton Summit HD from Sportsmans guide and it will be here in 2 days. Along with this I with the help of my cousin and his teenage son, have decided to make three of the old Popular Mechanics magazine style crossbows. I have been told before to start with the prod BUT I am currently accumulating the pieces for the stocks and triggers and my cousin and his son are supposed to be finding suitable leaf springs for the prods. I will be using Oak multiplex plywood, which is furniture grade and has 11 layers, for the stocks. I am planning to go to Kinko's and have the plans enlarged to full size in order to make templates.I was wondering if anyone had made one from these plans? This plan has a somewhat simple trigger compared to some triggers I have found online. I want as few moving parts as possible so i think this trigger will work. I know the tickler and nut is a little more simple but as the others are not familiar with this style of crossbow and are more comfortable with the rifle style modern crossbow we decided it would work better for our hunting needs than a medievel style. Any info you all have would be appreciated. I have exhausted all websites I can find by typing Homemade Crossbow, Do it yourself crossbow etc... as well as all youtube videos I can find on the subject. I have been through everything posted here as well but thought I would post in case someone had some advice stored away they had not posted yet.

Paul

Paul

genesis- Fresh Blood

Doesn't mean

I'm new to crossbows

- Posts : 11

Join date : 2011-02-09

Age : 67

Location : Marton,Manawatu,New Zealand

- Post n°2

Re: I am back with new project

Re: I am back with new project

Hi,Archer46176,I'm paul from New Zealand,& I too did an awful lot of trolling through the sites before settling on this fine one!The ''Popular Mechanics'' version of that dated crossbow has some comments posted by people who have made & used it,next to the searches listings,so they may be worth a read.My first replica(which I have yet to post a picture of) has a prod made from an old Ford prefect leafspring,no more than 5mm thick.Good luck!paul.

Geezer- Master Crossbowyer

- Posts : 1194

Join date : 2010-01-12

Age : 76

Location : Austin, Texas, USA

- Post n°3

Re: I am back with new project

Re: I am back with new project

Geezer here: I've seen samples of the old Popular Mechanics crossbow. It isn't a great bow, but should serve well enough. I don't recall if they recommended using steel cable, but if they did make such a recommendation.... DON'T, cable make a lousy string. See if you can find a supplier for Dacron B-50 or equivalent.

Have fun stormin' da castle!

Have fun stormin' da castle!

Archer46176- Fresh Blood

Doesn't mean

I'm new to crossbows

- Posts : 44

Join date : 2011-04-19

- Post n°4

Re: I am back with new project

Re: I am back with new project

Heya fellas, Thanks for the replies. I have not read any replies on the pop mech crossbows but I will look a little more closely to see if I can find them. Geezr I cannot remember it they recommended cable or not but after having seen some of the ones on youtube with cable i decided not to use it a good long while back. I have several spools of B-50 for making my flemmish strings for my longbows and that was whta I planned to use. I bought it at a traditional only archery shop awhile back for a sing... I am searching this evening for the crossbow bolts I will ned for the modern Horton that will be here tomorrow as it only comes with 3. After working on the first stock today and getting it glued up i have decided I am going to make one medievel style crossbow. I should have enough wood for 3 of the pop mech style and one of the medievel style. I may just get into this crossbow thing wholoe hog like I did with the slingshots I have made and use... I will try to post pics of my progress on my photobucket soon.

Paul

Paul

Ivo- Admin

- Posts : 1041

Join date : 2009-11-25

Age : 36

Location : NJ, USA

- Post n°5

Re: I am back with new project

Re: I am back with new project

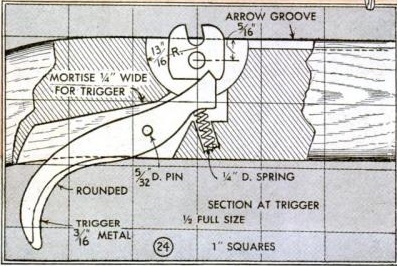

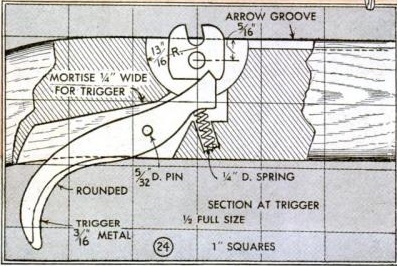

You must be referring to the vintage projects crossbow here? >>> http://www.vintageprojects.com/archery/cross-bow-leaf-spring.html

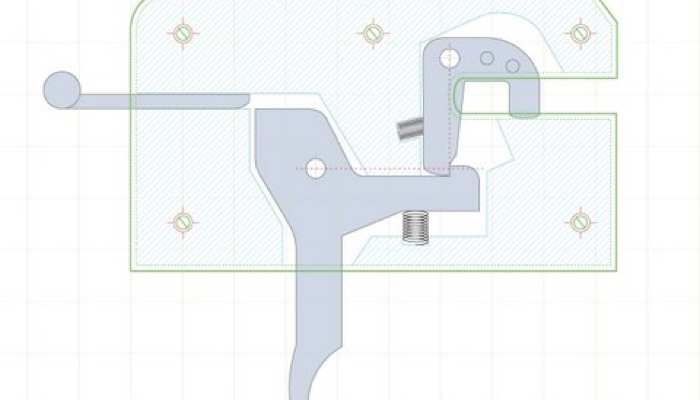

Trigger

The trigger isn't terrible, but what is bad is it's a bit unpredictable in my opinion.

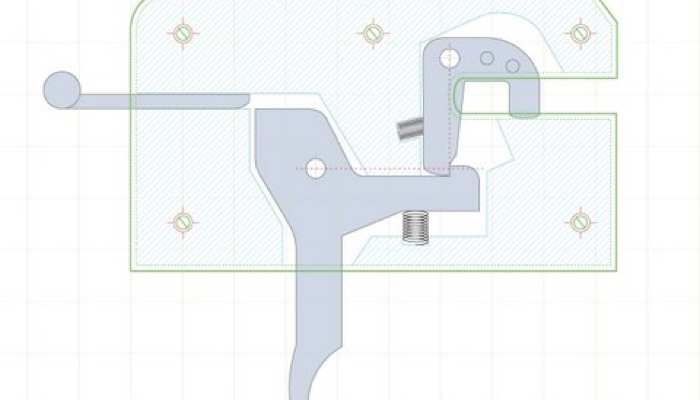

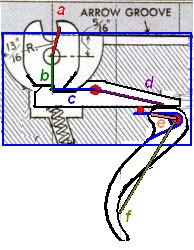

Take a look at this one for a second...

It's a top latch similar to the ones used on the Excalibur crossbows. This trigger diagram gives a good example of the few points that make a good trigger. For one...close attention should be paid to the "sear engagement angle to axel position relation"...you can see the dotted lines drawn from the axel points, they intersect and draws a 90 degree angle that is also the proper engagement angle of the sears.

This engagement angle is very important for the trigger to function safely and reliably...basically so the release hangs securely on the sear and isn't slipping or sliding anywhere.

Once you have that down... you can actually "roughly"(since friction isn't an easy thing to account for) calculate the trigger pull of various sear based triggers by simply looking at the components through the prism of "levers".

In the book Man Powere Bullets there is a bit of a diagram that gives a quick example of how that's done.

Now to touch ends on the trigger provided in the plans...it doesn't work like the classics shown above. Instead of the the sear preventing the rotation of the nut by hooking on to it, the trigger from plans is jamming the nut instead...thus preventing it's rotation. In my opinion that is a very unpredictable design as to calculating the resulting trigger pull...I'd rather go with something like this for simple reasons.

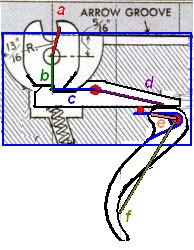

This one I just eye balled in paint, but if we break down the components and define their leverage ratio to one another we will get...

And assuming that we are using a 150lb prod the force applied to lever a will be 150lb. The leverage ratio of a:b is 1:1(again I'm just eye balling this) the sear is still holding 150lb. Next is the ratio of c:d which is 1:2 meaning the load is cut in half due to the mechanical advantage that d has over c and the resulting load is now 75lb. Now here is where the magic happens...the ratio of e to f is 1:4 meaning the force required to pull the trigger has been cut down to 1/4 of those 75lbs...giving us a theoretical 18lbs of pull (the actual number will be higher or lower...read on ).

).

I'm saying theoretical, because the interaction between b and c is different from the other levers on the diagram. They are position perpendicular to one another(at a 90 degree angle) with b hanging on to the sear located at the end of c.

The 75lb that I mentioned above are fictional...the actual force brought onto the sear by the nut is not going to be 150lb, considering the levers are positioned perpendicular the force required to move the sear is the force necessary to overcoming the friction brought on by the 150lb which is usally less, but I can't give you any solid numbers and here's why VVV.

This is where the engagement angle that I spoke of earlier plays a crucial role. A fraction of a degree to the right and the sear will cut into the nut creating more friction and giving you a tighter trigger, while same to the left and the nut might slip if you bang on the stock and the crossbow will go off. Therefore I recommend keeping the angle a strict 90 degrees for your own and everyone's safety.

Check out the Wiki for more info on the subject ... http://crossbow.wikia.com/wiki/Designing_medieval_nut_and_trigger_crossbow_locks

A few hings on reducing the friction in order to lighten the release:

Stock

The stock can be easily checked out by getting a piece of styrofoam and carving a rough shape with a hot wire/rod/knife(what ever is in stock ) or making a test stock out of some pine. Check with the stock making topic ... all the info is there, now you just need to get a feel of it:

) or making a test stock out of some pine. Check with the stock making topic ... all the info is there, now you just need to get a feel of it:

https://thearbalistguild.forumotion.com/t20-custom-shoulder-stock-ideas-videos-pictures-plans-diagrams

Prod

As for the prod...well it's really up to you...just make sure you get a new leaf spring...I think they're around $15-$30...which is pretty much the amount you would pay for a #150 fiberglass limb(string and tips included).

Trigger

The trigger isn't terrible, but what is bad is it's a bit unpredictable in my opinion.

Take a look at this one for a second...

It's a top latch similar to the ones used on the Excalibur crossbows. This trigger diagram gives a good example of the few points that make a good trigger. For one...close attention should be paid to the "sear engagement angle to axel position relation"...you can see the dotted lines drawn from the axel points, they intersect and draws a 90 degree angle that is also the proper engagement angle of the sears.

This engagement angle is very important for the trigger to function safely and reliably...basically so the release hangs securely on the sear and isn't slipping or sliding anywhere.

Once you have that down... you can actually "roughly"(since friction isn't an easy thing to account for) calculate the trigger pull of various sear based triggers by simply looking at the components through the prism of "levers".

In the book Man Powere Bullets there is a bit of a diagram that gives a quick example of how that's done.

Now to touch ends on the trigger provided in the plans...it doesn't work like the classics shown above. Instead of the the sear preventing the rotation of the nut by hooking on to it, the trigger from plans is jamming the nut instead...thus preventing it's rotation. In my opinion that is a very unpredictable design as to calculating the resulting trigger pull...I'd rather go with something like this for simple reasons.

This one I just eye balled in paint, but if we break down the components and define their leverage ratio to one another we will get...

And assuming that we are using a 150lb prod the force applied to lever a will be 150lb. The leverage ratio of a:b is 1:1(again I'm just eye balling this) the sear is still holding 150lb. Next is the ratio of c:d which is 1:2 meaning the load is cut in half due to the mechanical advantage that d has over c and the resulting load is now 75lb. Now here is where the magic happens...the ratio of e to f is 1:4 meaning the force required to pull the trigger has been cut down to 1/4 of those 75lbs...giving us a theoretical 18lbs of pull (the actual number will be higher or lower...read on

I'm saying theoretical, because the interaction between b and c is different from the other levers on the diagram. They are position perpendicular to one another(at a 90 degree angle) with b hanging on to the sear located at the end of c.

The 75lb that I mentioned above are fictional...the actual force brought onto the sear by the nut is not going to be 150lb, considering the levers are positioned perpendicular the force required to move the sear is the force necessary to overcoming the friction brought on by the 150lb which is usally less, but I can't give you any solid numbers and here's why VVV.

This is where the engagement angle that I spoke of earlier plays a crucial role. A fraction of a degree to the right and the sear will cut into the nut creating more friction and giving you a tighter trigger, while same to the left and the nut might slip if you bang on the stock and the crossbow will go off. Therefore I recommend keeping the angle a strict 90 degrees for your own and everyone's safety.

Check out the Wiki for more info on the subject ... http://crossbow.wikia.com/wiki/Designing_medieval_nut_and_trigger_crossbow_locks

A few hings on reducing the friction in order to lighten the release:

- Polishing the sears and axels. With axels it's no big deal, however with sears you must take great care not to screw up the sear engagement angle, as polishing can and will remove material if you're not careful.

- Lubrication - Your choice. My personal down and dirty favorite is graphite...old locksmith trick still used today.

Stock

The stock can be easily checked out by getting a piece of styrofoam and carving a rough shape with a hot wire/rod/knife(what ever is in stock

https://thearbalistguild.forumotion.com/t20-custom-shoulder-stock-ideas-videos-pictures-plans-diagrams

Prod

As for the prod...well it's really up to you...just make sure you get a new leaf spring...I think they're around $15-$30...which is pretty much the amount you would pay for a #150 fiberglass limb(string and tips included).

Basilisk120- Moderator

- Posts : 548

Join date : 2010-03-01

Age : 45

Location : Arizona

- Post n°6

Re: I am back with new project

Re: I am back with new project

Looking forward to what the project actually turns out. I have looked at those plans before so am very interested.

Ivo - Thanks for the break down on the trigger mechanism. Looks like simple statics but still nice to see. (and it was a nice refresher on statics)

Ivo - Thanks for the break down on the trigger mechanism. Looks like simple statics but still nice to see. (and it was a nice refresher on statics)

Archer46176- Fresh Blood

Doesn't mean

I'm new to crossbows

- Posts : 44

Join date : 2011-04-19

- Post n°7

Re: I am back with new project

Re: I am back with new project

IVO, That was a great reply. I was planning to use a different trigger that I found on youtube that seemed to be a pretty decent design. I am really glad you posted the trigger break down it may come in helpful in the future if i decide to get into the crossbow thing like i did the slingshot thing...lol... I just got the Horton Summit today, it is much better than the Barnett I had several years ago but it only came with 3 unmarked Horton brand bolts. I will be sourcing botls for it soon. I think the reason I am leaning toward the leaf spring at this point in time is to prove that I could do it if I had to. I tend to be one of the fellas you read about who likes to be prepared just in case things in society don't always go the way we plan...lol... Never know when you may not be able to buy things and will have to make them out of necessity...

The stock is all glued up and will be further roughed out tomorrow, it sat all night clamped up and most of today as well. This first one will be a light crossbow just to get the mechanics figured out a bit and give me some experience to build off of in the future. I am going to glue up 3 more pieces of the multiplex furniture grade 3/4" plywood tomorrow in order to make the stock for my medievel style crossbow.

One question about the old tickler and nut triggers though... On some of the more modern trigger systems using nuts the string is pulled back which engaes the nut and pushed it back to cock it in position and hold the string but what I have noticed on some videos is that the nut spins freely when fired. So my question is do you have to spin the nut by hand to set it amnd make it engage the tickler? I should have pics of the stock tomorrow evening so i will post the link to photobucket tomorrow evening.

Paul

The stock is all glued up and will be further roughed out tomorrow, it sat all night clamped up and most of today as well. This first one will be a light crossbow just to get the mechanics figured out a bit and give me some experience to build off of in the future. I am going to glue up 3 more pieces of the multiplex furniture grade 3/4" plywood tomorrow in order to make the stock for my medievel style crossbow.

One question about the old tickler and nut triggers though... On some of the more modern trigger systems using nuts the string is pulled back which engaes the nut and pushed it back to cock it in position and hold the string but what I have noticed on some videos is that the nut spins freely when fired. So my question is do you have to spin the nut by hand to set it amnd make it engage the tickler? I should have pics of the stock tomorrow evening so i will post the link to photobucket tomorrow evening.

Paul

Todd the archer- Crossbow Junkie

I live here!

- Posts : 581

Join date : 2010-02-25

Age : 62

Location : sellersville,pa.

- Post n°8

Re: I am back with new project

Re: I am back with new project

The answer to your last question is yes.

Todd

Todd

Ivo- Admin

- Posts : 1041

Join date : 2009-11-25

Age : 36

Location : NJ, USA

- Post n°9

Re: I am back with new project

Re: I am back with new project

Youtube isn't the best place to find info on crossbow yet. I plan on making a Youtube Channel for the forum once I have a few tutorials and some projects finished, but till then it's all in progress, some on the forum. And lets not forget the "New Member Links" panel on the right >>> Crossbow Building Wiki / Crossbowman's Den.

Good luck.

Ivo

Good luck.

Ivo

stealthmicro- Fresh Blood

Doesn't mean

I'm new to crossbows

- Posts : 2

Join date : 2015-01-30

- Post n°10

Re: I am back with new project

Re: I am back with new project

nice trigger designs! I want to go with the style in your last pic, Im

starting my own build soon here.

im

following your cool build here Keep up the good work!!

starting my own build soon here.

im

following your cool build here Keep up the good work!!

stm2010- Fresh Blood

Doesn't mean

I'm new to crossbows

- Posts : 46

Join date : 2013-01-08

- Post n°11

Re: I am back with new project

Re: I am back with new project

The calculation of c:d=1:2 is wrong, maybe 1:8.

Ivo wrote:You must be referring to the vintage projects crossbow here? >>> http://www.vintageprojects.com/archery/cross-bow-leaf-spring.html

Trigger

The trigger isn't terrible, but what is bad is it's a bit unpredictable in my opinion.

Take a look at this one for a second...

It's a top latch similar to the ones used on the Excalibur crossbows. This trigger diagram gives a good example of the few points that make a good trigger. For one...close attention should be paid to the "sear engagement angle to axel position relation"...you can see the dotted lines drawn from the axel points, they intersect and draws a 90 degree angle that is also the proper engagement angle of the sears.

This engagement angle is very important for the trigger to function safely and reliably...basically so the release hangs securely on the sear and isn't slipping or sliding anywhere.

Once you have that down... you can actually "roughly"(since friction isn't an easy thing to account for) calculate the trigger pull of various sear based triggers by simply looking at the components through the prism of "levers".

In the book Man Powere Bullets there is a bit of a diagram that gives a quick example of how that's done.

Now to touch ends on the trigger provided in the plans...it doesn't work like the classics shown above. Instead of the the sear preventing the rotation of the nut by hooking on to it, the trigger from plans is jamming the nut instead...thus preventing it's rotation. In my opinion that is a very unpredictable design as to calculating the resulting trigger pull...I'd rather go with something like this for simple reasons.

This one I just eye balled in paint, but if we break down the components and define their leverage ratio to one another we will get...

And assuming that we are using a 150lb prod the force applied to lever a will be 150lb. The leverage ratio of a:b is 1:1(again I'm just eye balling this) the sear is still holding 150lb. Next is the ratio of c:d which is 1:2 meaning the load is cut in half due to the mechanical advantage that d has over c and the resulting load is now 75lb. Now here is where the magic happens...the ratio of e to f is 1:4 meaning the force required to pull the trigger has been cut down to 1/4 of those 75lbs...giving us a theoretical 18lbs of pull (the actual number will be higher or lower...read on).

I'm saying theoretical, because the interaction between b and c is different from the other levers on the diagram. They are position perpendicular to one another(at a 90 degree angle) with b hanging on to the sear located at the end of c.

The 75lb that I mentioned above are fictional...the actual force brought onto the sear by the nut is not going to be 150lb, considering the levers are positioned perpendicular the force required to move the sear is the force necessary to overcoming the friction brought on by the 150lb which is usally less, but I can't give you any solid numbers and here's why VVV.

This is where the engagement angle that I spoke of earlier plays a crucial role. A fraction of a degree to the right and the sear will cut into the nut creating more friction and giving you a tighter trigger, while same to the left and the nut might slip if you bang on the stock and the crossbow will go off. Therefore I recommend keeping the angle a strict 90 degrees for your own and everyone's safety.

Check out the Wiki for more info on the subject ... http://crossbow.wikia.com/wiki/Designing_medieval_nut_and_trigger_crossbow_locks

A few hings on reducing the friction in order to lighten the release:

- Polishing the sears and axels. With axels it's no big deal, however with sears you must take great care not to screw up the sear engagement angle, as polishing can and will remove material if you're not careful.

- Lubrication - Your choice. My personal down and dirty favorite is graphite...old locksmith trick still used today.

Stock

The stock can be easily checked out by getting a piece of styrofoam and carving a rough shape with a hot wire/rod/knife(what ever is in stock) or making a test stock out of some pine. Check with the stock making topic ... all the info is there, now you just need to get a feel of it:

https://thearbalistguild.forumotion.com/t20-custom-shoulder-stock-ideas-videos-pictures-plans-diagrams

Prod

As for the prod...well it's really up to you...just make sure you get a new leaf spring...I think they're around $15-$30...which is pretty much the amount you would pay for a #150 fiberglass limb(string and tips included).

Private messages

Private messages