The design to be tested: Reverse limb configuration + full compound system.

To speed the process, I've built 2 straight limbs, using 2 layers of clear fiberglass and 2 strips of action bamboo (the laminated limbs are made using 4 laminations totaling 7 cm thickness, 4cm wideness and 45 cm in length). I will say that the limbs are pretty soft (I estimate a max draw weight of just 20kg), but, for testing purpose will be just perfect

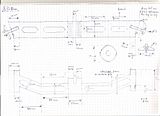

I also designed a trigger system and made calculations regarding limbs alignment : the limbs will have to be oriented 30 grades away from the stock in order to achieve a draw length of 50cm. Aiming a draw length longer than the limbs, I had to place the trigger in the back of the riser - from this perspective, I had to design the riser a little wider, each limb being 10cm away from the stock (to be able to cook the bow by hand and not to get the rope passing over the riser)

I also built 2 pulleys (round and with the hole in the middle). Here I made a mistake, building the pulleys with 2 x 6mm thick ball bearing inside - this leading to a 15mm overall thickness (I think that it will be too much to cut a 15mm hole in the 40mm limbs tops). This week i will build another pulleys using just 1 ball bearing, leading to just 10mm thickness.

Unlike Ivo, i choose to build the metal spare parts to a machine shop to get better accuracy (especially for the riser that will have to be perfect aligned and for the pulleys ...). Up to the end of this week I will have to have ready the trigger mechanism components and the new pulleys. Next week I should get the riser and to start assembly the crossbow. I will start to take and display pictures as the works will progress.

;

; ;

; ;

;

;

;

;

;

;

;

Private messages

Private messages