First topic message reminder :

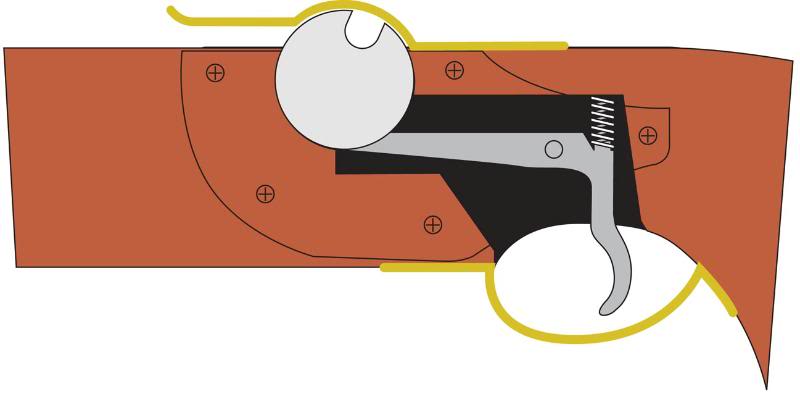

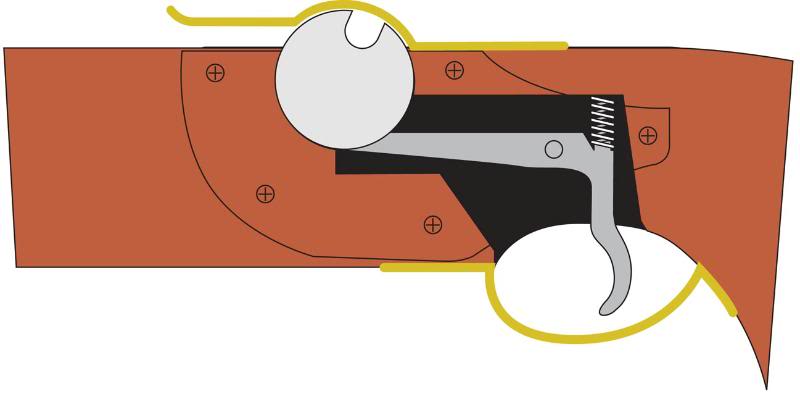

This was the initial plan I came up with for my first complete build, designed around Alchem's 200ish pound prod. A few things changed along the way during construction, but I stuck pretty religiously with their plans for the business end. My goal is medieval military utility, throwing short, heavy bolts, but I wanted a more modern grip, trigger and shoulder stock.

And this is an updated detail of the trigger/lock mech.

I cut the stock from a solid chunk of walnut. I had planned on a contrasting wood for the track, and this became a necessity when I discovered the walnut to be a bit splintery and soft in the track area. So the insert was much thicker than I had originally planned, but this had the added benefit of making cutting the cavity for the trigger much more straightforward. I originally thought I would use some exotic and spectacular hardwood, but I had a stick of oak from Lowe's just the right size on my workbench so there you have it. I like the contrast, and I know I have a strong glue joint, but I sunk a couple of hidden screws into each end just to be safe. I drilled the socket for the nut all the way through and carved a couple of oak inserts to glue in later, once I had fitted the nut. One is in place in this photo.

Here's most of the bits I fabricated, also one of 6 prototype bolts I built. It's 1/2" oak dowel, 1/2" aluminum tube, and 1/2" steel rod, and weighs about 2.2 ounces. I think it's pretty good considering I don't have tools to make them properly, I'm proud of them but it's doubtful I'll make any more since I found out I can get 1/2" quarrel points from Richard Head Longbows for $1.76 each.

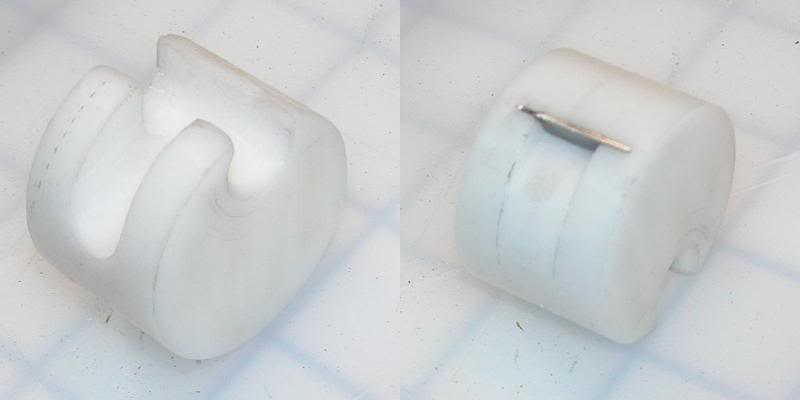

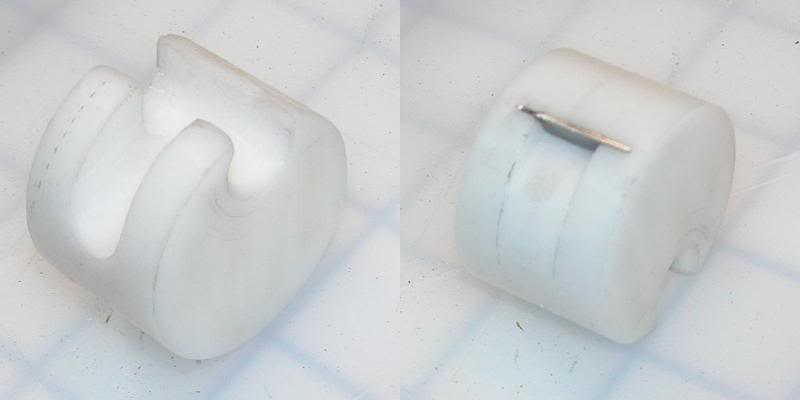

I ordered a couple of Derlin nut blanks from Alchem, but in the meantime found I could get my own 1.5" Derlin rod from Amazon, and did so. I also got a slab of 1" UHMW for future experiments, as well as UHMW adhesive tape. I cut a couple of blanks and got carving with my dremel and files. It was the first time I worked with this plastic and I'm pleased with the results so far, though installing the steel sear reinforcement was a bear. I cut the slot for it with an abrasive wheel in the dremel, then cut a utility knife blade to the same circular shape as the cut, with slightly roughed side edges for grip, then carefully and gingerly pounded the crap out of it with a big hammer until it was seated properly and I couldn't pull it out. That derlin is tough stuff.

Finally, here's a shot of the completed lock area. The wood finish is just linseed oil and beeswax. I've left the track groove very shallow so that I can fine tune that once the prod is installed and I can see how deep it should be based on the position of the string. The tongue is also not in it's final shape, I'm sure.

That's about as far as I can go until I have the prod and irons in my hands, and probably further than I should have gone. In the meantime I'm thinking about what kind of sights I'd like to install, and also thinking of making a bench spanning device out of a scissor-type car jack.

Whaddya think?

Gnome

This was the initial plan I came up with for my first complete build, designed around Alchem's 200ish pound prod. A few things changed along the way during construction, but I stuck pretty religiously with their plans for the business end. My goal is medieval military utility, throwing short, heavy bolts, but I wanted a more modern grip, trigger and shoulder stock.

And this is an updated detail of the trigger/lock mech.

I cut the stock from a solid chunk of walnut. I had planned on a contrasting wood for the track, and this became a necessity when I discovered the walnut to be a bit splintery and soft in the track area. So the insert was much thicker than I had originally planned, but this had the added benefit of making cutting the cavity for the trigger much more straightforward. I originally thought I would use some exotic and spectacular hardwood, but I had a stick of oak from Lowe's just the right size on my workbench so there you have it. I like the contrast, and I know I have a strong glue joint, but I sunk a couple of hidden screws into each end just to be safe. I drilled the socket for the nut all the way through and carved a couple of oak inserts to glue in later, once I had fitted the nut. One is in place in this photo.

Here's most of the bits I fabricated, also one of 6 prototype bolts I built. It's 1/2" oak dowel, 1/2" aluminum tube, and 1/2" steel rod, and weighs about 2.2 ounces. I think it's pretty good considering I don't have tools to make them properly, I'm proud of them but it's doubtful I'll make any more since I found out I can get 1/2" quarrel points from Richard Head Longbows for $1.76 each.

I ordered a couple of Derlin nut blanks from Alchem, but in the meantime found I could get my own 1.5" Derlin rod from Amazon, and did so. I also got a slab of 1" UHMW for future experiments, as well as UHMW adhesive tape. I cut a couple of blanks and got carving with my dremel and files. It was the first time I worked with this plastic and I'm pleased with the results so far, though installing the steel sear reinforcement was a bear. I cut the slot for it with an abrasive wheel in the dremel, then cut a utility knife blade to the same circular shape as the cut, with slightly roughed side edges for grip, then carefully and gingerly pounded the crap out of it with a big hammer until it was seated properly and I couldn't pull it out. That derlin is tough stuff.

Finally, here's a shot of the completed lock area. The wood finish is just linseed oil and beeswax. I've left the track groove very shallow so that I can fine tune that once the prod is installed and I can see how deep it should be based on the position of the string. The tongue is also not in it's final shape, I'm sure.

That's about as far as I can go until I have the prod and irons in my hands, and probably further than I should have gone. In the meantime I'm thinking about what kind of sights I'd like to install, and also thinking of making a bench spanning device out of a scissor-type car jack.

Whaddya think?

Gnome

Private messages

Private messages